JCB Electronic Service Tool is a powerful heavy truck scanner that comes with JCB Service Master 4 V1.73.3 software in CD. This tool supports multiple languages, making it convenient for users from different regions.

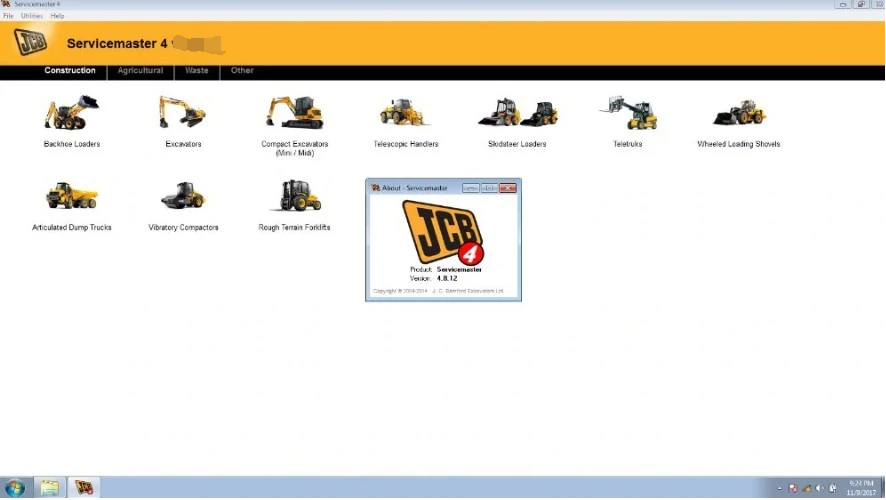

One of the key features of the JCB Electronic Service Tool is its gateway application, JCB Service Master. This application allows users to link a large number of Vehicle Support Applications using one familiar interface. It acts as a graphical tool for selecting the target vehicle from a group of Vehicle Families and triggering the desired Service Tool Application. This eliminates the need for users to remember and select individual service tools for specific machines.

The JCB Service Master also offers additional features that are essential for any JCB project. It includes a multi-language editing tool, which allows for text string translation for all JCB applications. Users can also select a localized language translation for each JCB application, ensuring clear communication and ease of use.

The JCB Electronic Service Tool has several highlights that make it a valuable asset for heavy truck diagnostics and maintenance. It can read fault codes and rank them in order of importance, allowing users to prioritize and address critical issues first. It also has the capability to calibrate, parameterize ECM, and program blocks. Additionally, it can conduct dropping service intervals, ensuring that vehicles are serviced at the right time to maintain optimal performance.

This tool is compatible with the JCB Service Master 4 software, ensuring that users have access to the latest updates and features. It works seamlessly with the CAN protocol in the OBD II system, providing accurate and reliable diagnostic results. The JCB Electronic Service Tool also includes instructions for use, repair, and diagnostics of JCB engines, as well as engines from Isuzu, Deutz, and Cummins. Users can also access full original JCB repair and service manuals and bulletins, making it a comprehensive solution for all their needs.

Furthermore, the JCB Electronic Service Tool offers programming of special parameters, which can be ordered separately. This allows users to customize and optimize their vehicles according to specific requirements. The tool supports multiple languages, including English, German, Spanish, French, Italian, and Portuguese, ensuring that users can navigate and use the tool in their preferred language.

The JCB Electronic Service Tool supports a wide range of models and engines, including JS Range, JZ70, BackHoe Loader, Loadall 2007-, Loadall 2007+, Robot, Teletruk, Midi Excavator, Dump Truck, Fastrac 2000-3000 Series, Fastrac 8250 Series 1, Fastrac 8250 Series 2, Fastrac 7000 Series 1, Large Wheel Loading Shovels, Vibromax, JCB Dieselmax Engine, JCB Engine (IPU OEM), JCB Engine (Base Engine OEM), JCB Generators, and LiveLink.

In conclusion, the JCB Electronic Service Tool with Free SM4 V1.73.3 Software is a reliable and comprehensive solution for heavy truck diagnostics and maintenance. Its user-friendly interface, multi-language support, and wide range of features make it an essential tool for professionals in the industry.