How Can Measurement Instrumentation Aid Industrial Quality Control

When it comes to manufacturing, quality control is crucial. In order to maintain the brand’s image and match consumer expectations, every product that exits the assembly line has to adhere to strict criteria. The measurement instrumentation is one of the most important elements in accomplishing this aim. Quality control in production relies on measurement instrumentation, from precise tools to sophisticated sensors.

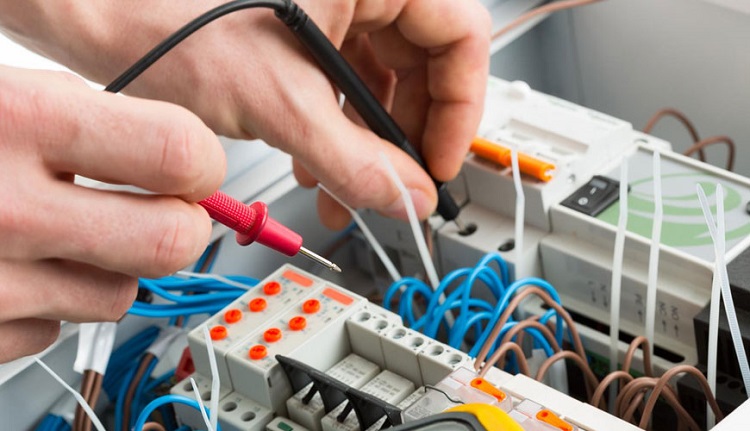

Precise Quality Control through Precise Measurement

In industrial facilities, measurement equipment acts as the eyes and ears of quality control. These tools let firms monitor every stage of production by accurately measuring dimensions, temperature, pressure, and more. A digital caliper provides precise machining, while a thermocouple checks heat treatment temperature variation.

Monitoring in Real Time and Feedback Loops

Key variables may be monitored in real time in production processes by integrating measurement instrumentation. This makes it possible to quickly identify deviations from the intended parameters and to take appropriate remedial action. Load cells in metal stamping machines may detect force fluctuations and trigger modifications to preserve component dimensions. The real-time feedback loop stops faulty items from moving down the manufacturing line, saving time and resources.

Keeping Standards and Regulations Compliant

In the industrial sector, quality control often entails following stringent industry norms and laws. Instrumentación de medida, which offers unbiased data proving adherence to predetermined standards, is essential for guaranteeing adherence to these regulations. Precise equipment helps producers achieve regulatory requirements and avoid expensive fines by measuring coating thickness for corrosion resistance or electrical conductivity for safety compliance.

Streamlining Procedures to Cut Costs and Increase Efficiency

Measurement instrumentation improves industrial processes for efficiency and cost savings in addition to maintaining quality requirements. Manufacturers may boost productivity by correctly monitoring energy use, material utilization, and cycle times. A flow meter in a chemical processing facility may fine-tune constituent amounts, lowering waste and manufacturing costs.

Making Data-driven Decisions Easy to Make

To remain competitive in today’s data-driven industrial environment, making well-informed decisions is essential. Large volumes of data are produced by measurement equipment on several facets of the manufacturing process. Analyzing and interpreting data may help firms understand performance patterns, enhance, and optimize quality control techniques. Statistical process control can identify variability and lead process stability improvements using sensor data.

Maintaining Brand Reputation and Customer Satisfaction

Delivering goods that continuously meet or beyond customer expectations is the main objective of quality control in manufacturing. Measurement equipment is essential to reaching this goal since it makes sure that all products meet pre-established criteria for quality. Manufacturers can protect their image in the market, increase consumer happiness, and cultivate brand loyalty by reducing flaws and inconsistencies.

Conclusion

Measurement equipment is essential to preserving production quality control. Manufacturers may develop continuously and compete in the modern marketplace by using measurement instrumentation.

Commenti recenti