How Do Mechanical Transmission Products Contribute to Reducing Energy Loss in Machinery

Mechanical transmission products play a crucial role in the operation of machinery across various industries. Their primary function is to transmit power from one part of the machine to another, facilitating movement and functionality. However, an often overlooked aspect of these components is their contribution to energy efficiency. In this article, we will explore how mechanical transmission products contribute to reducing energy loss in machinery, focusing on key factors such as precision engineering, material selection, and design optimization.

How Do Mechanical Transmission Products Contribute to Reducing Energy Loss in Machinery?

Precision Engineering in Mechanical Transmission

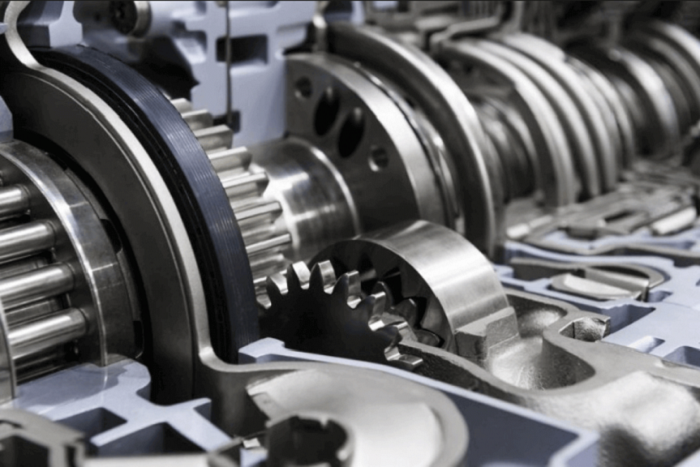

One of the most significant factors in reducing energy loss in machinery is the precision engineering of productos de transmision mecanica. Components such as gears, belts, and chains are designed with exact specifications to match the requirements of the machinery they are used in. This precision minimizes friction and wear, which are primary sources of energy loss in mechanical systems.

For instance, gears that are designed with precise tooth profiles can mesh more effectively, leading to smoother operation and less energy wasted in the form of heat. Similarly, belts and chains that are manufactured to exact tolerances can reduce slippage and maintain better alignment, ensuring that the power transmitted from one component to another is done so with minimal loss. The result is a more efficient system that requires less energy to perform the same amount of work.

Material Selection and Its Impact on Energy Efficiency

The materials used in the construction of mechanical transmission products have a direct impact on their efficiency. Different materials have varying properties, such as strength, weight, and resistance to wear and heat, all of which can influence the amount of energy lost during operation.

For example, using lightweight materials like certain alloys or composites can reduce the overall mass of the components, leading to less inertia and, therefore, lower energy consumption. Additionally, materials with low friction coefficients can reduce the amount of energy lost to heat due to friction between moving parts. By carefully selecting materials that offer a balance of strength and low friction, manufacturers can create mechanical transmission products that contribute to a significant reduction in energy loss.

Design Optimization for Energy Savings

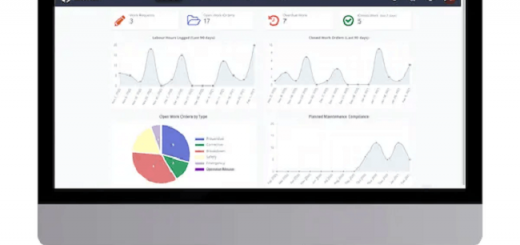

Another critical aspect of reducing energy loss in machinery through mechanical transmission products is design optimization. This involves analyzing and refining the design of components to enhance their performance and minimize energy wastage.

One approach to design optimization is the use of advanced computer modeling and simulation tools. These tools allow engineers to model the behavior of mechanical transmission products under various operating conditions and identify areas where energy losses occur.

Conclusion

Mechanical transmission products are vital components in machinery, and their role in reducing energy loss cannot be overstated. In an industrial landscape where energy efficiency is increasingly important, the focus on optimizing mechanical transmission products for reduced energy loss is not just beneficial—it is necessary. By understanding and implementing these principles, manufacturers and operators can achieve significant energy savings, leading to more sustainable and cost-effective operations.

Commenti recenti