When it comes to maintaining and repairing commercial trucks, a heavy-duty scan tool is a must-have for fleet operators and maintenance technicians. These scanning tools provide detailed information about a truck’s engine, transmission, and other systems, helping to optimize performance and minimize downtime.

One of the best investments you can make is a truck scan tool, whether you’re a professional mechanic or someone who wants to avoid expensive diagnostic fees at your local dealership. These scan tools are easy to use and can provide valuable data for diagnosing and repairing unexpected breakdowns.

Let’s take a look at some of the top truck scan tools on the market:

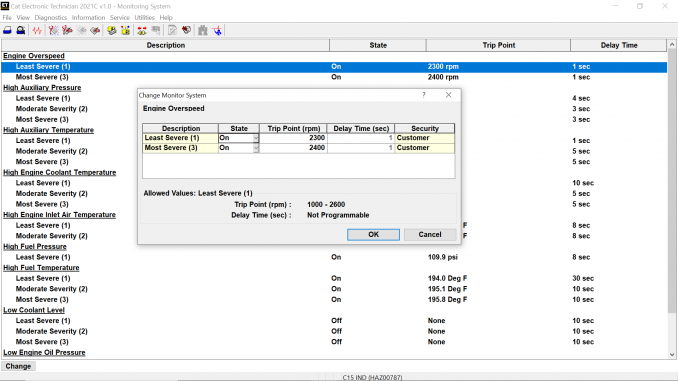

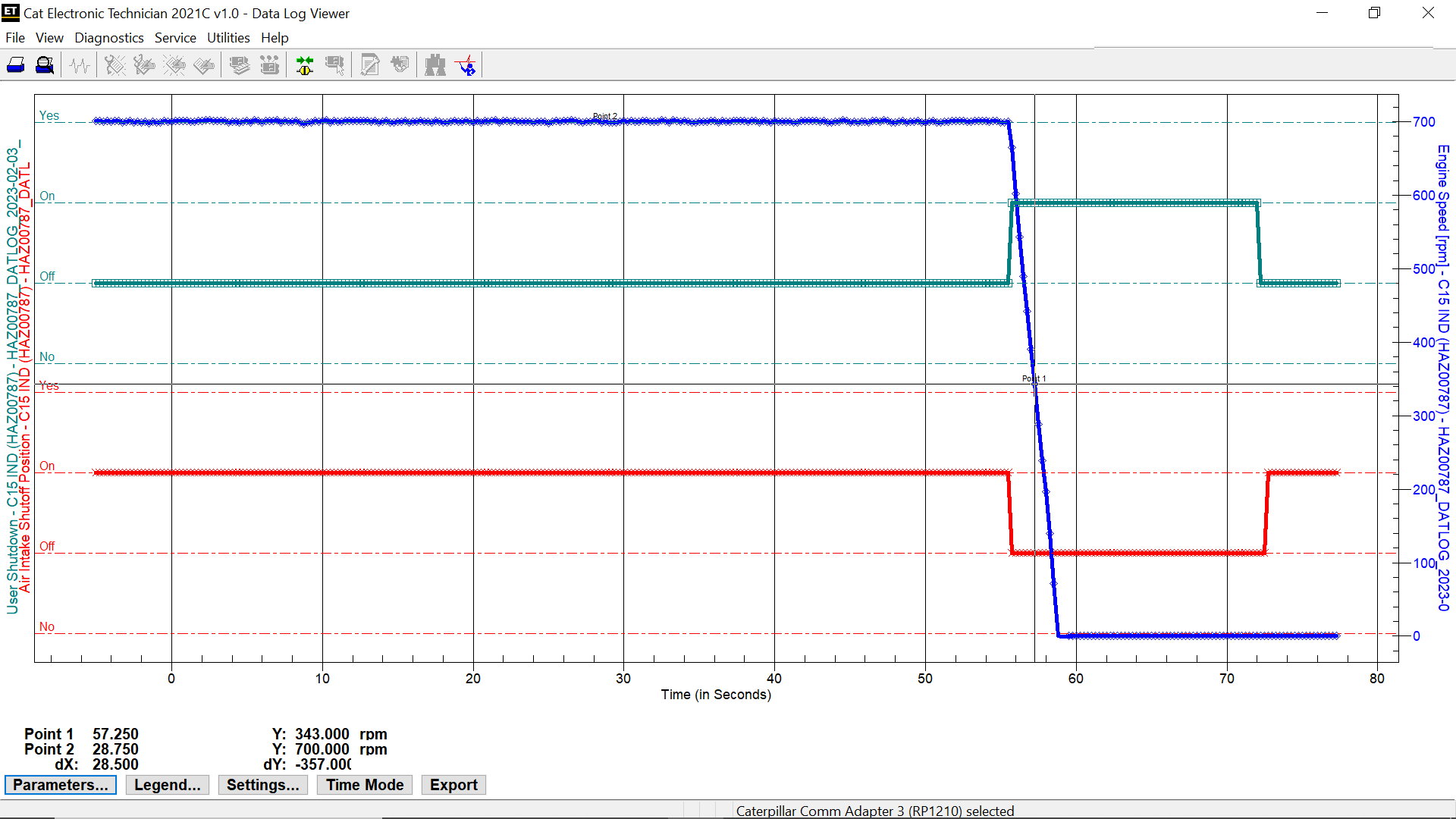

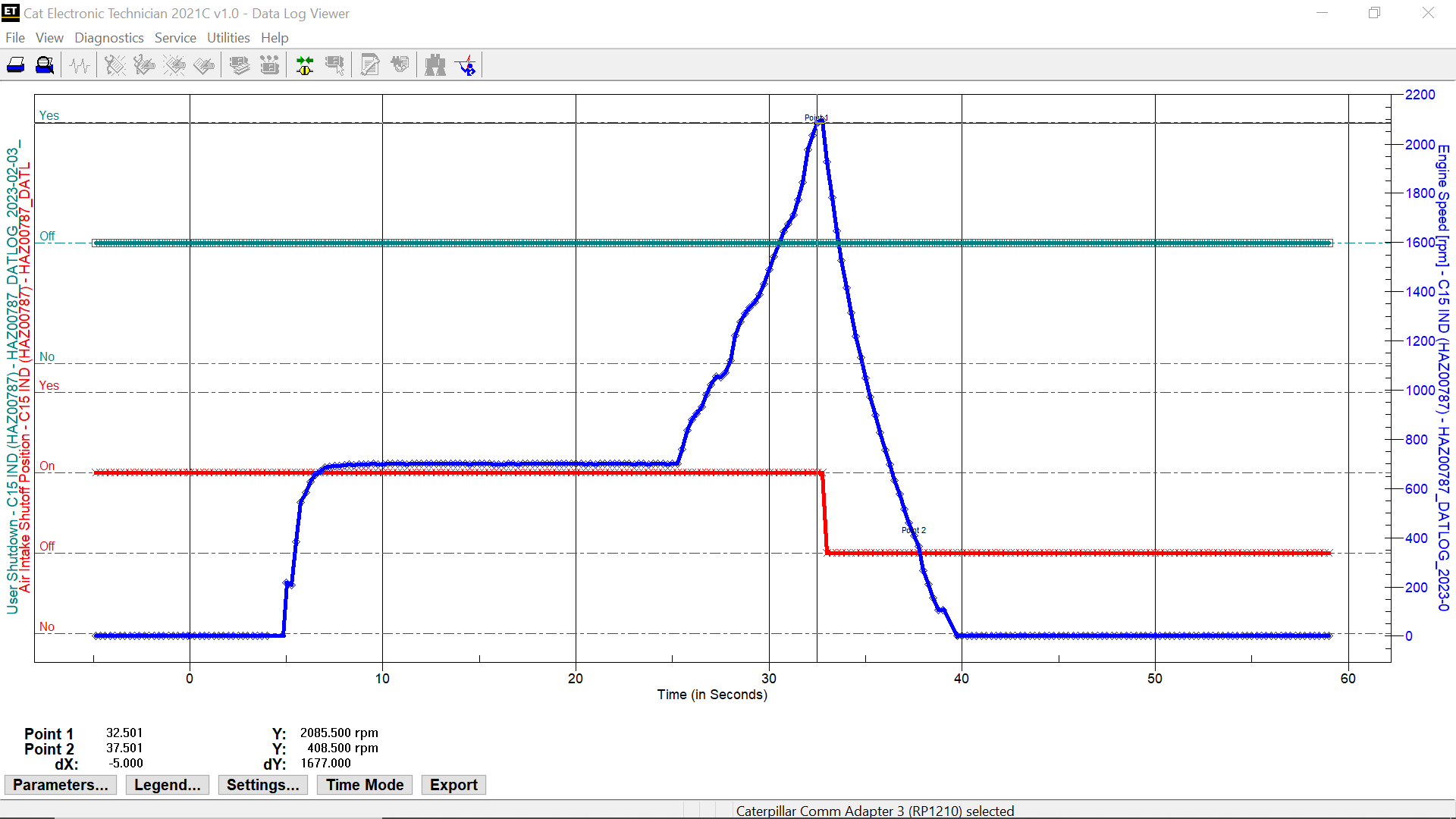

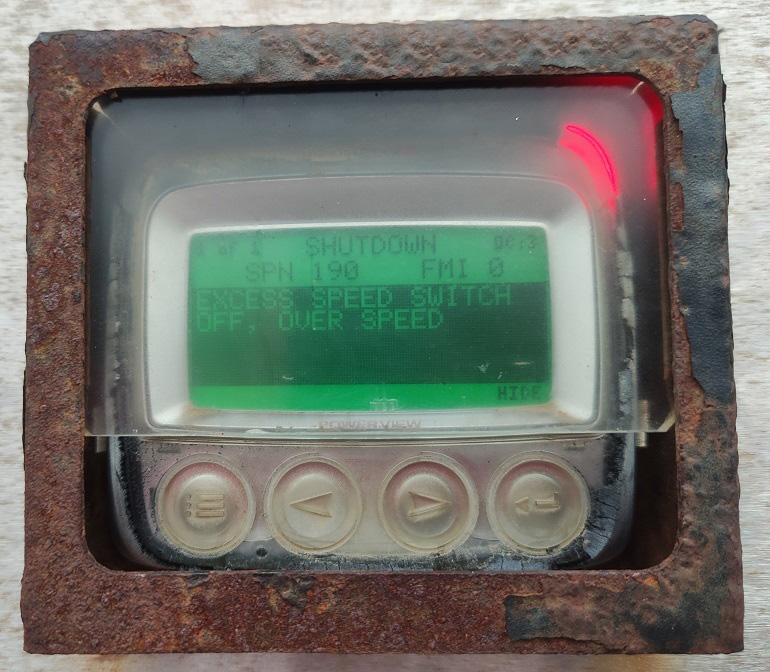

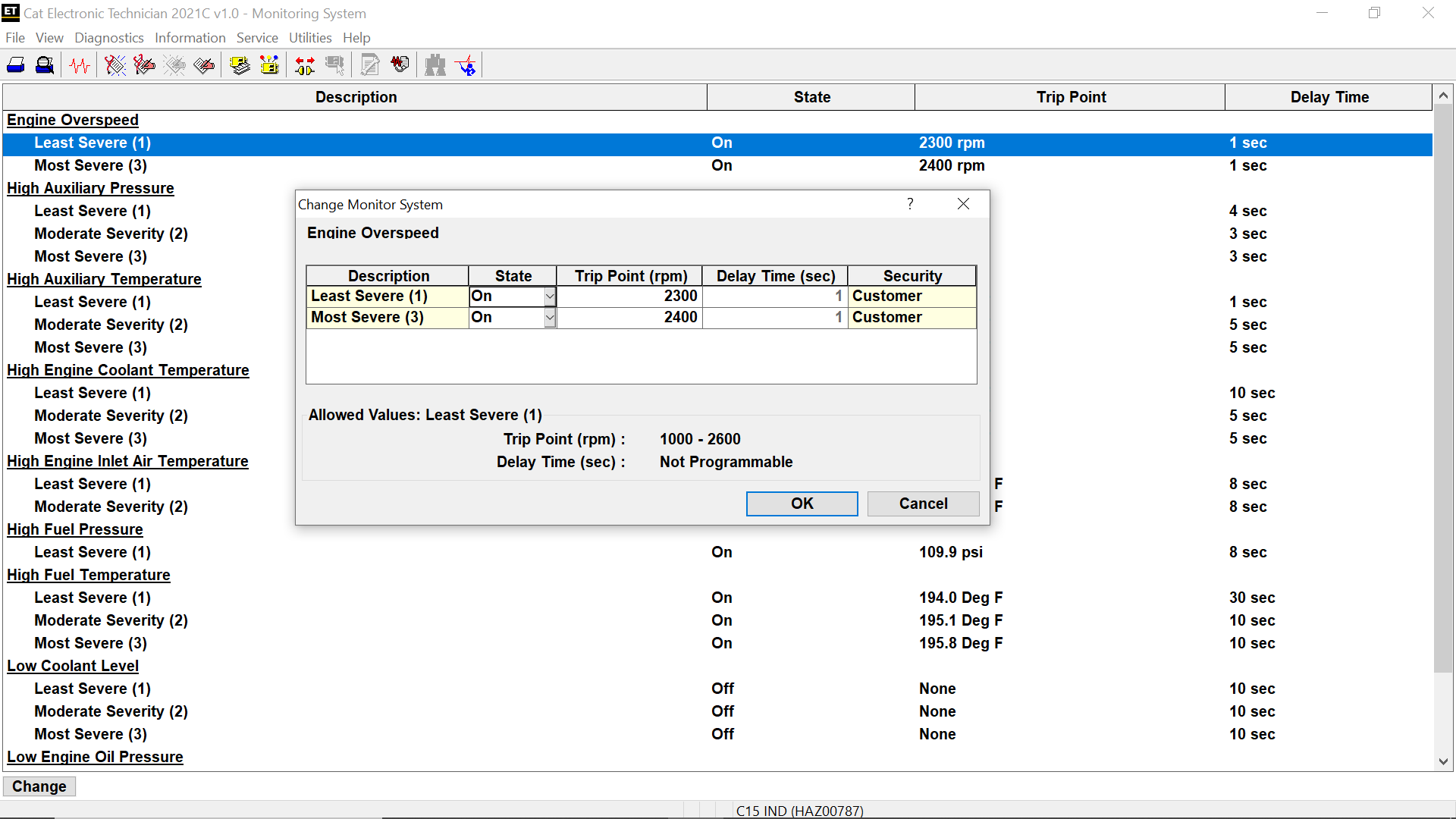

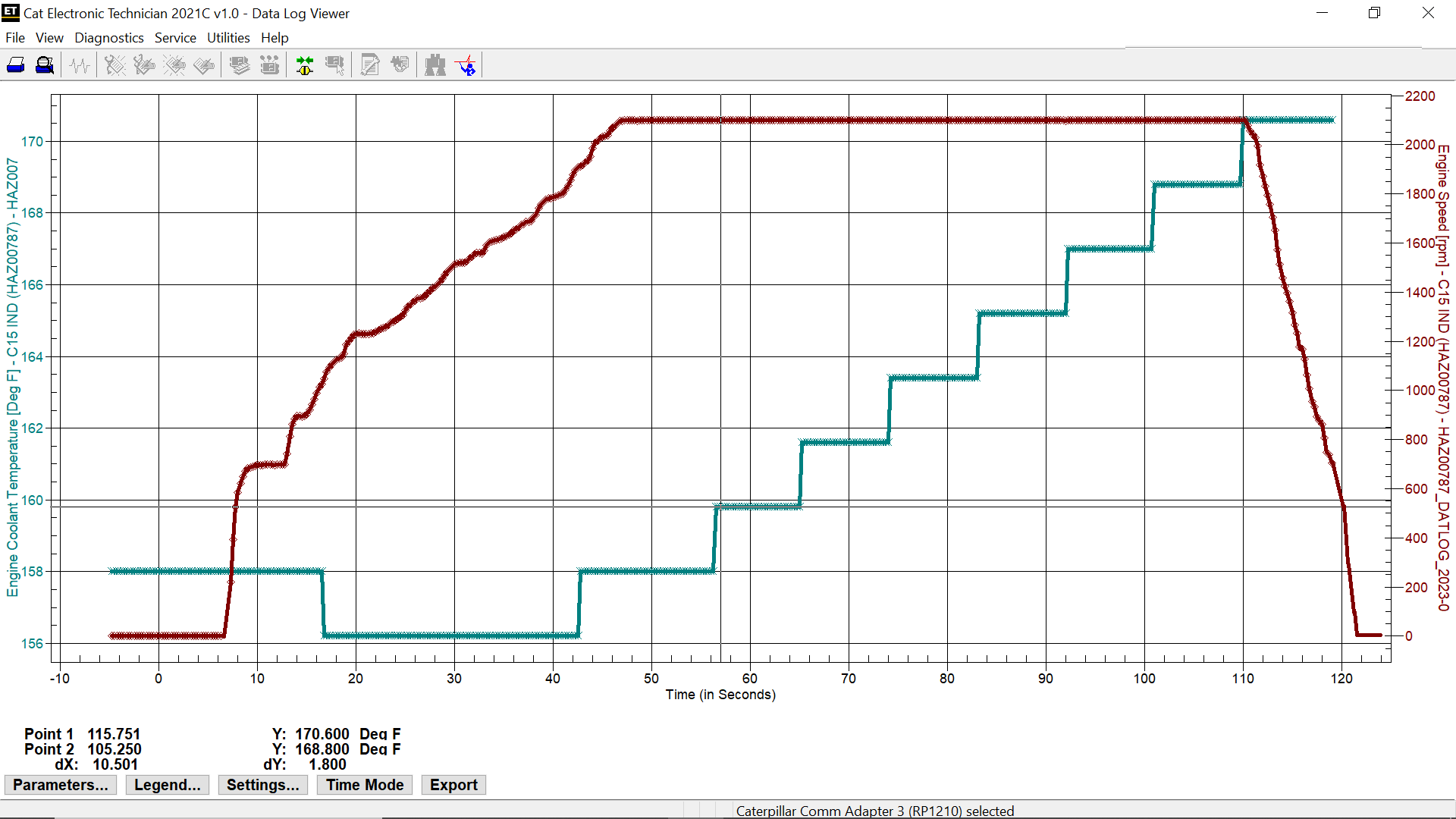

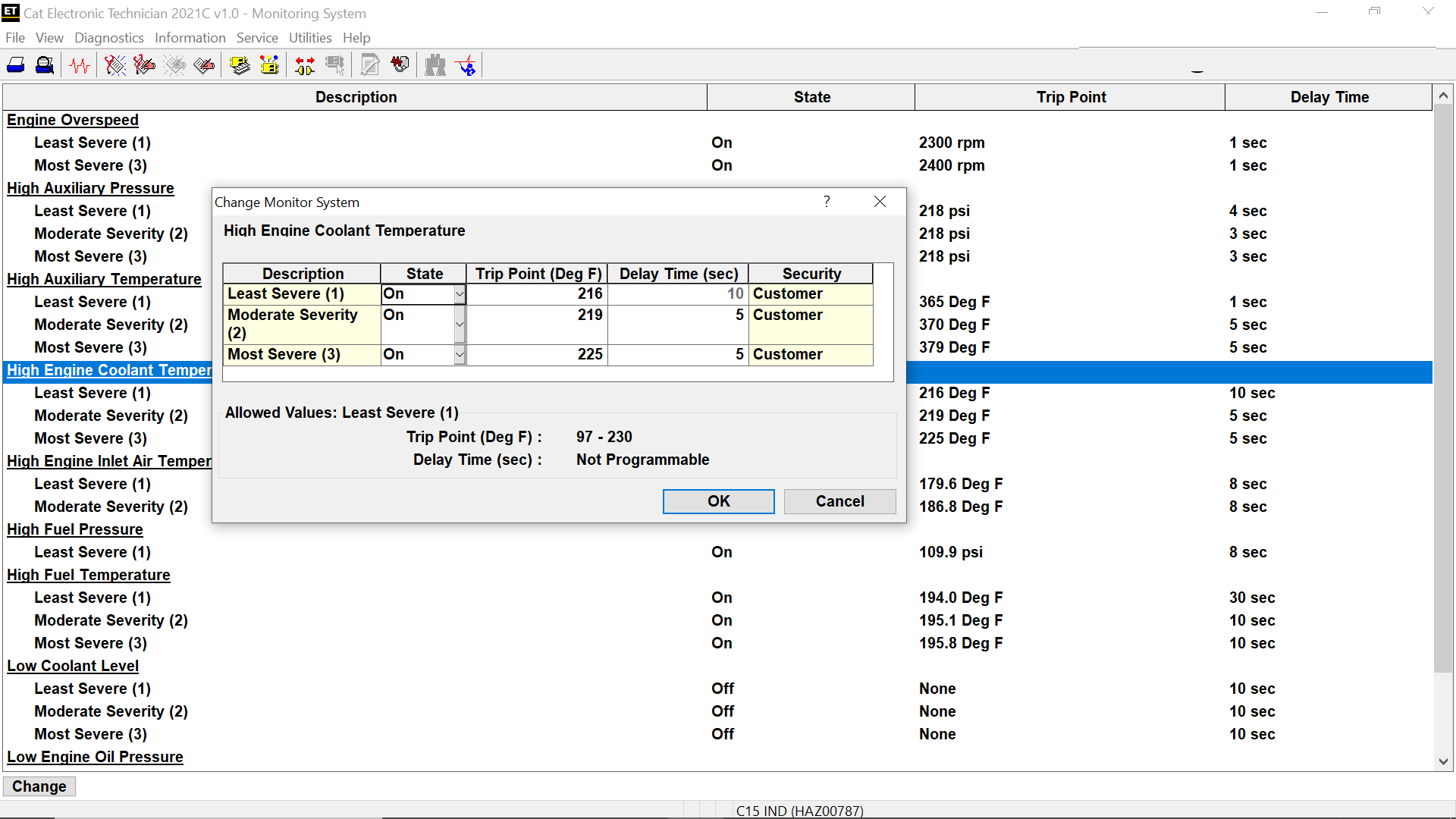

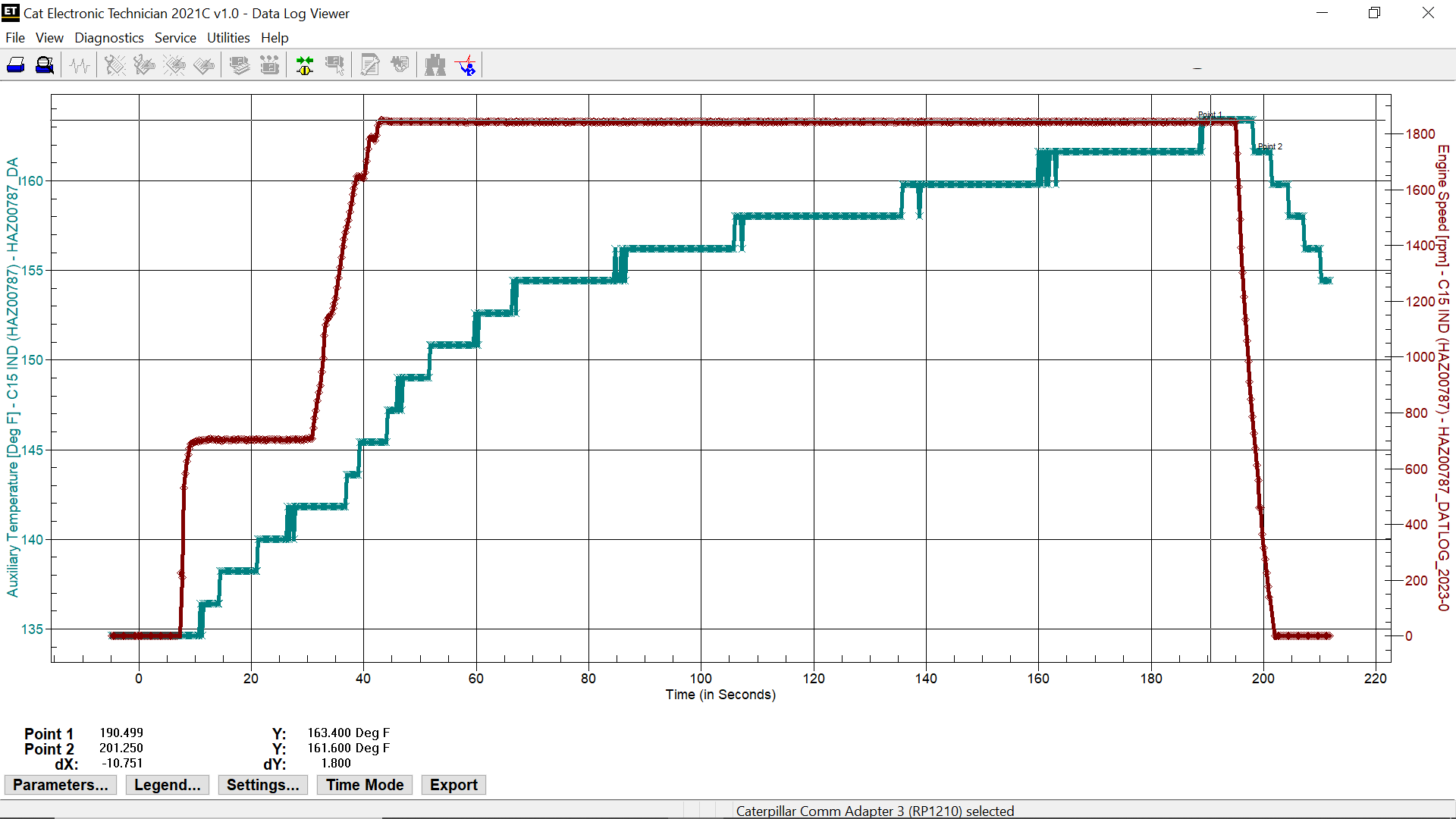

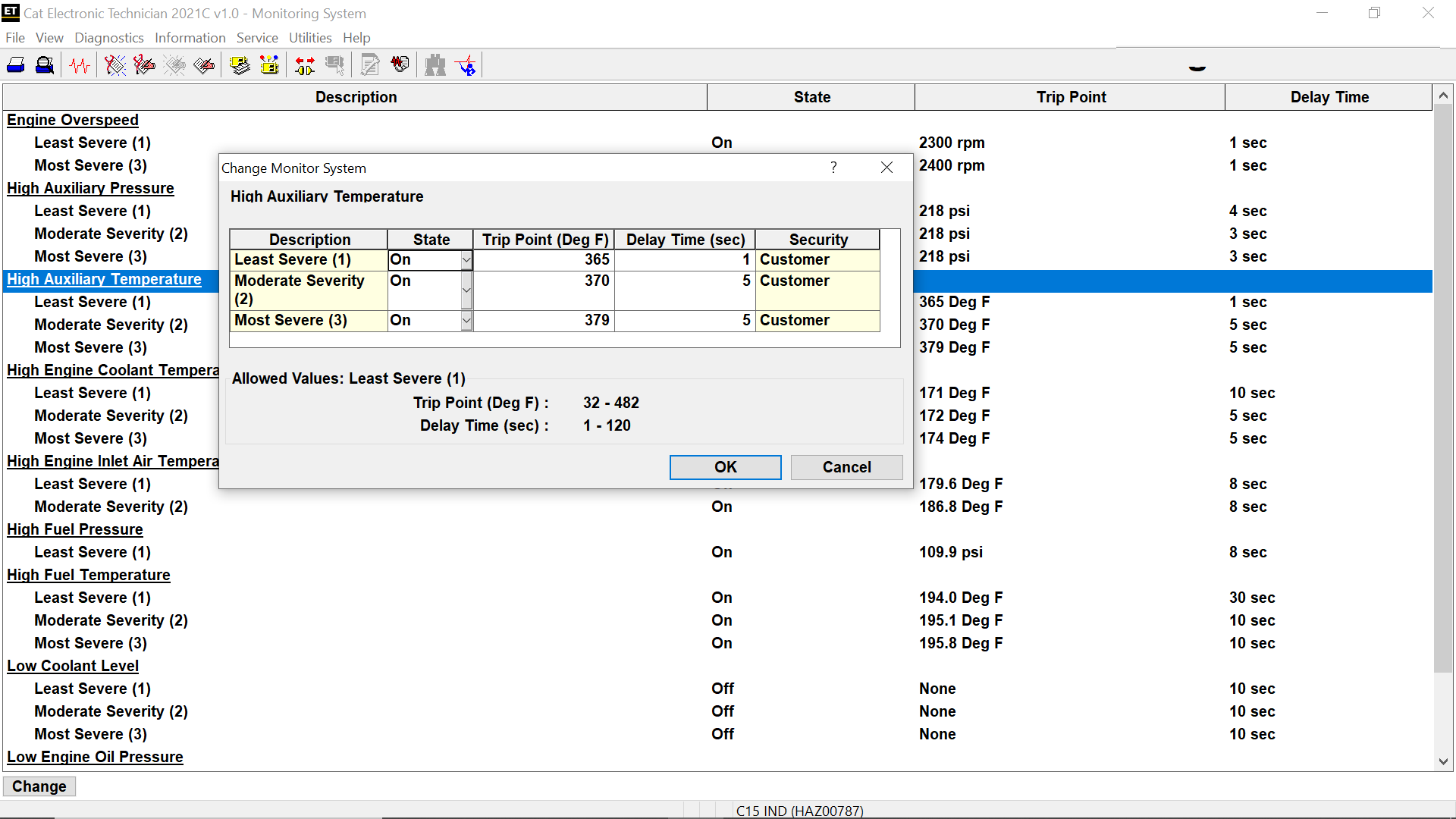

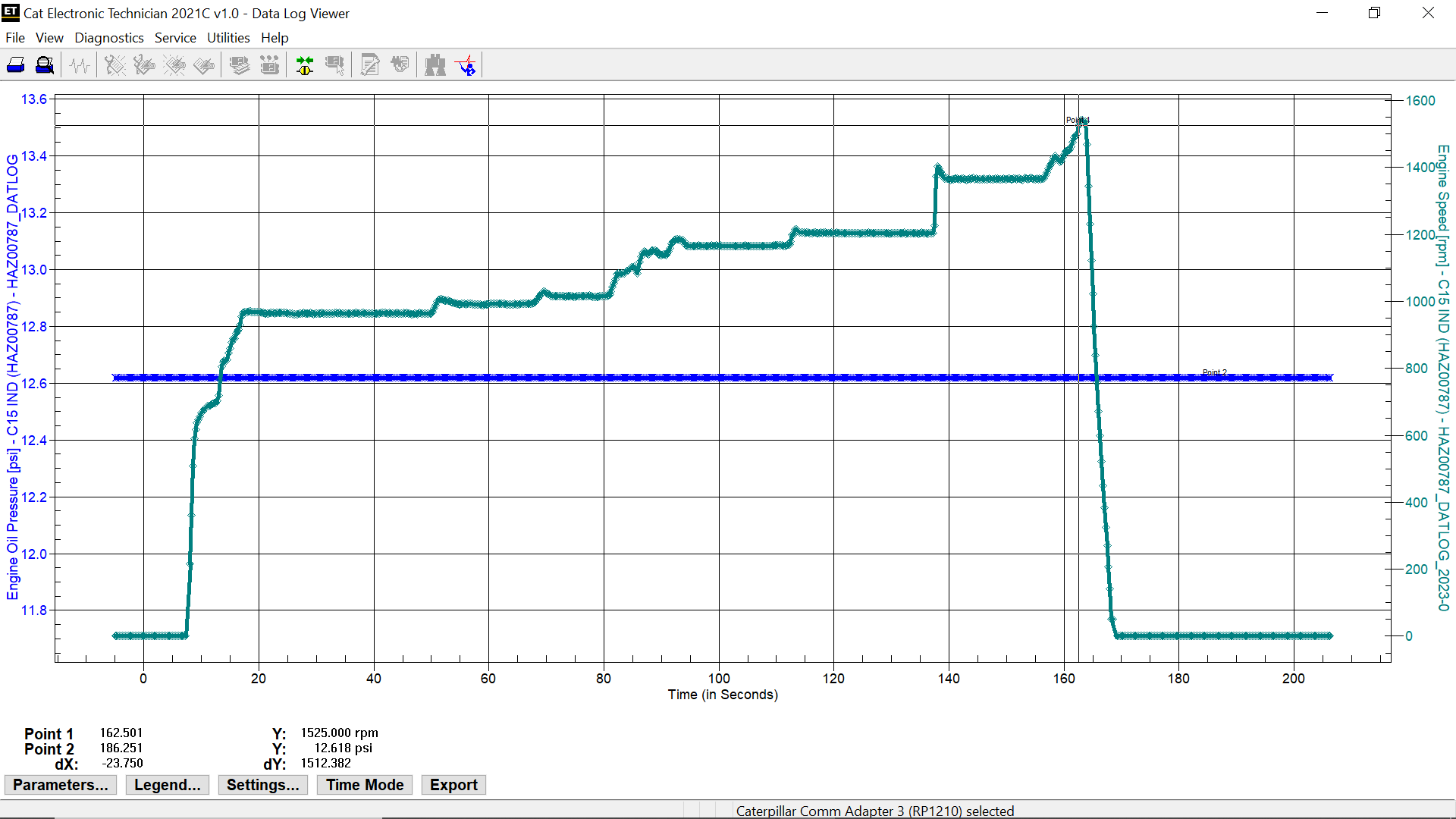

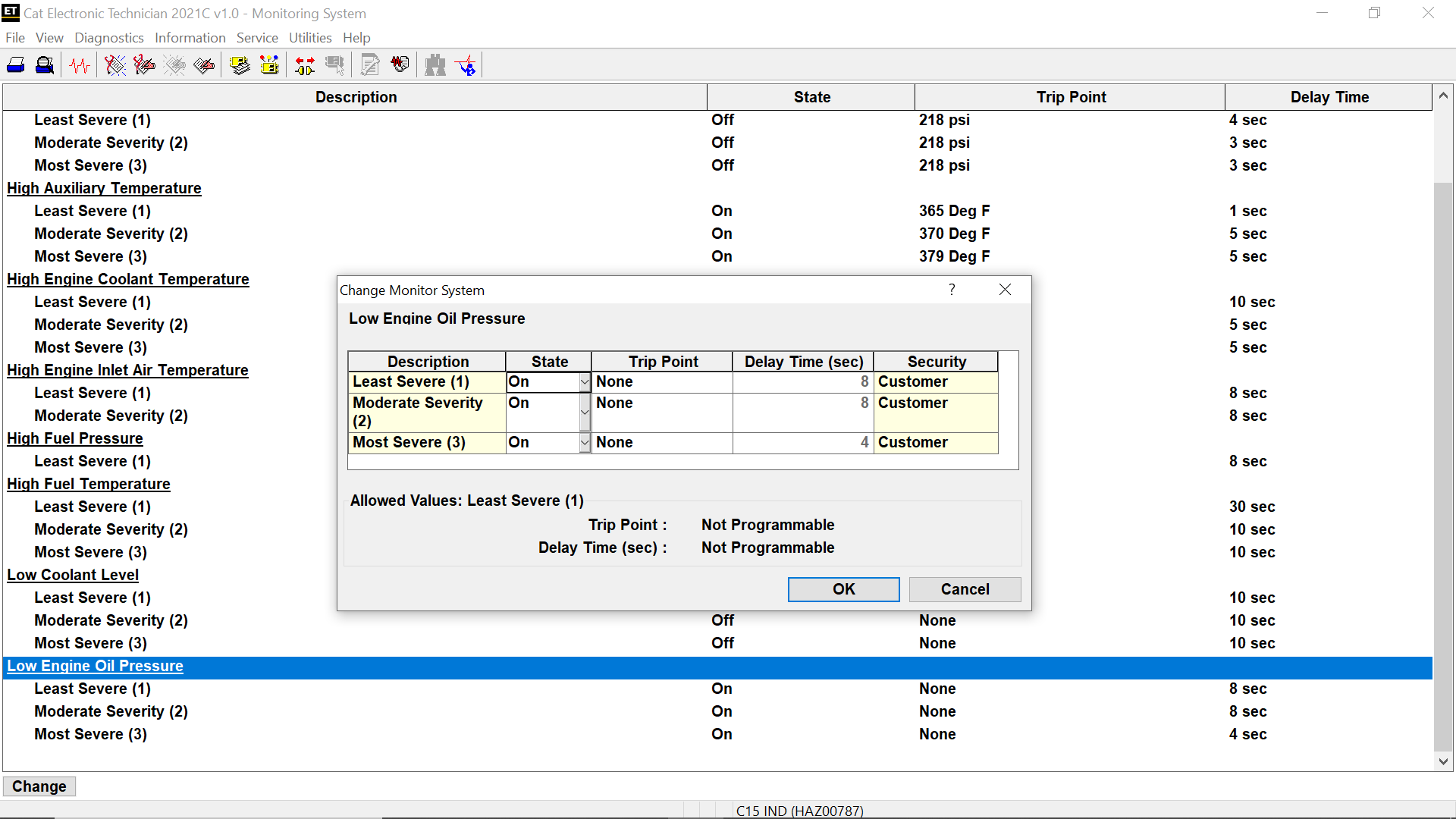

1. Caterpillar ET 2023A Electronic Technician Diagnostics: This diagnostic software from Caterpillar is compatible with a wide range of Caterpillar engines, allowing users to diagnose and troubleshoot potential problems. It works offline, so you don’t need an internet connection to use it. Simply download the software from the AutoSoft.Group website, install it using the activation code provided, and you’re ready to go.

2. JPRO Professional Truck Diagnostic Scanner Tool Noregon JPro DLA+ 2.0 Adapter Kit: This comprehensive diagnostic tool is compatible with all car models, making it a great addition to any professional service center. It provides real-time diagnostic solutions and accurate vehicle information, making it easy to diagnose and repair your truck without leaving your garage. It also includes bi-directional functions and the ability to print diagnostic reports for your customers.

3. VOCOM II Heavy-Duty Vehicle Diagnostics Kit: Designed to work with the PTT TechTool Software, this diagnostic kit is perfect for maintaining heavy-duty vehicles like trucks, buses, and construction equipment. It supports a wide range of Volvo trucks, buses, and construction equipment models, allowing users to diagnose and troubleshoot potential issues. It also comes with the latest software version and provides complete vehicle health status reports.

4. Inspection Diagnostic Tool DDT SCR DPF G2 Scan DCU ECU: This diagnostic tool is suitable for both light trucks and heavy-duty vehicles, making it a versatile option. It supports multiple languages and comes with powerful functions for checking ECU information, managing fault codes, and testing engines. It is compatible with Doosan excavators, forklifts, and engine systems, allowing for comprehensive diagnostics and programming.

No matter which truck diagnostic scanner tool you choose, you can rest assured that it will be easy to use and provide valuable information for diagnosing and repairing your truck. Investing in a reliable scan tool can save you time and money by identifying potential problems early and keeping your truck running smoothly. So, don’t wait – get your hands on a truck diagnostic scanner tool today!