2023A lastest Version CAT Caterpillar ET Diagnostic Adapter III Cat Communication Adapter 3(Real Caterpillar ET3 Adapter III)

Caterpillar Comm Adapter III – diagnostic scanner interface is a cat group dealer workshop diagnostic tool built to work with Caterpillar heavy vehicles and Caterpillar engines. It is the latest generation of the cat Communication Adapter group and replaces the cat Comm Adapter II & the old 466-6258 and 317-7487 tool number.

Caterpillar scan tool includes:

CAT Comm Adapter III (part # 317-7485)

CD with the drivers

USB Cable (From device to your computer)

J1939/J1708 Cable (from device to your truck)

Hard Shell Case with foam inserts

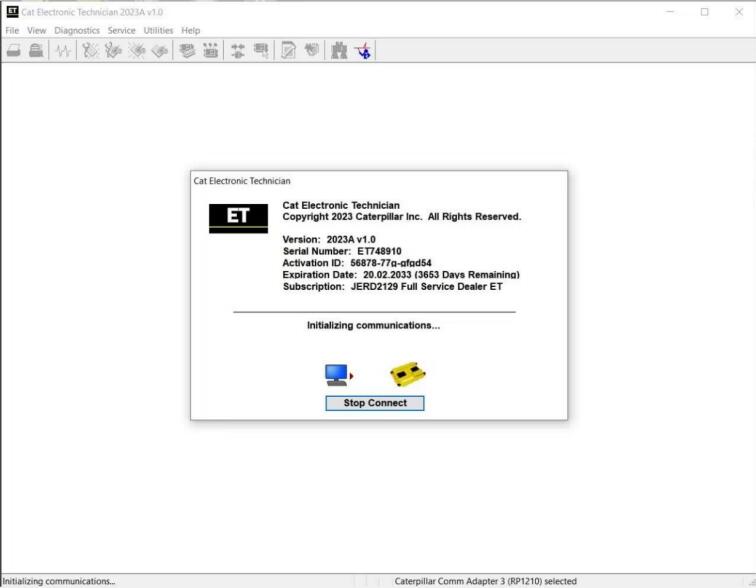

Caterpillar ET 2023A

Caterpillar Electronic Technician (Cat ET) is a service tool designed to run on a personal computer (PC) under Microsoft Windows. It will communicate with the Electronic Control Modules (ECMs) through a communication data link thus allowing you to diagnose existing and potential problems, configure the product and obtain data for analysis.

With the CAT Diagnostic Tool, you can:

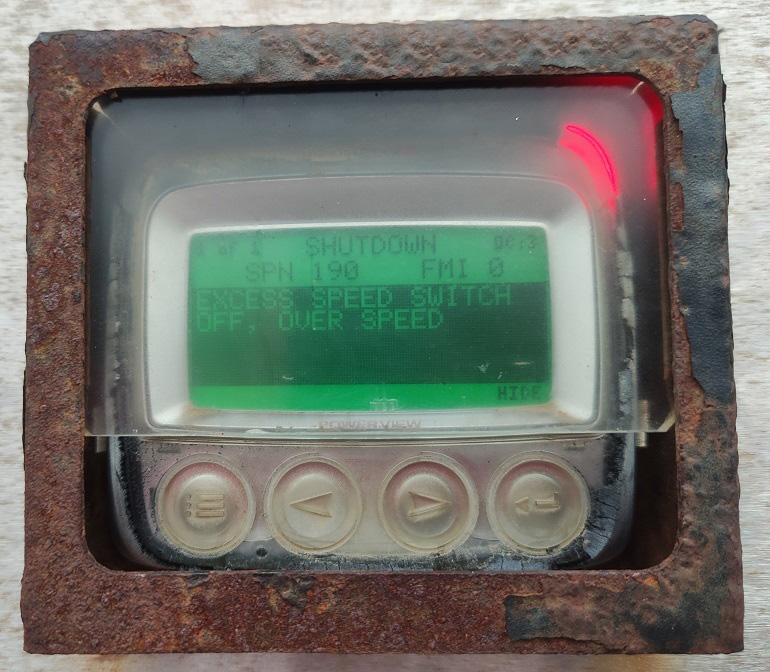

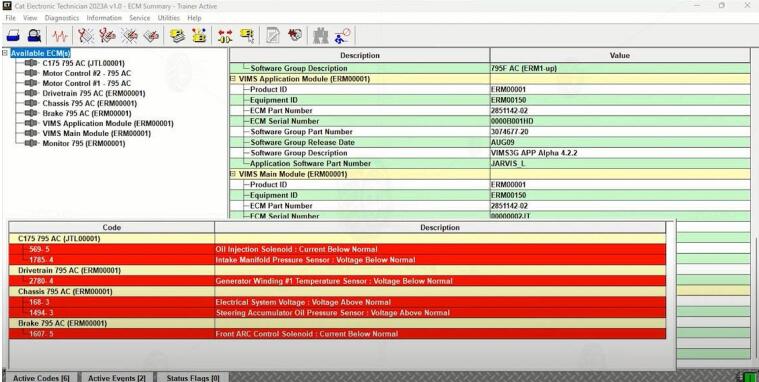

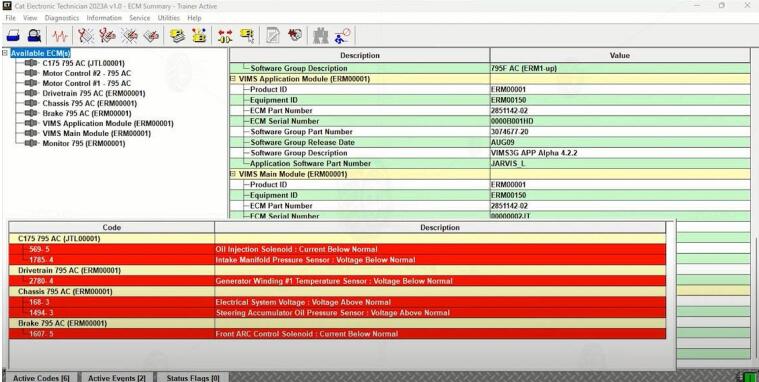

View active and logged diagnostics

View events where irregularities occurred and were logged by the ECM

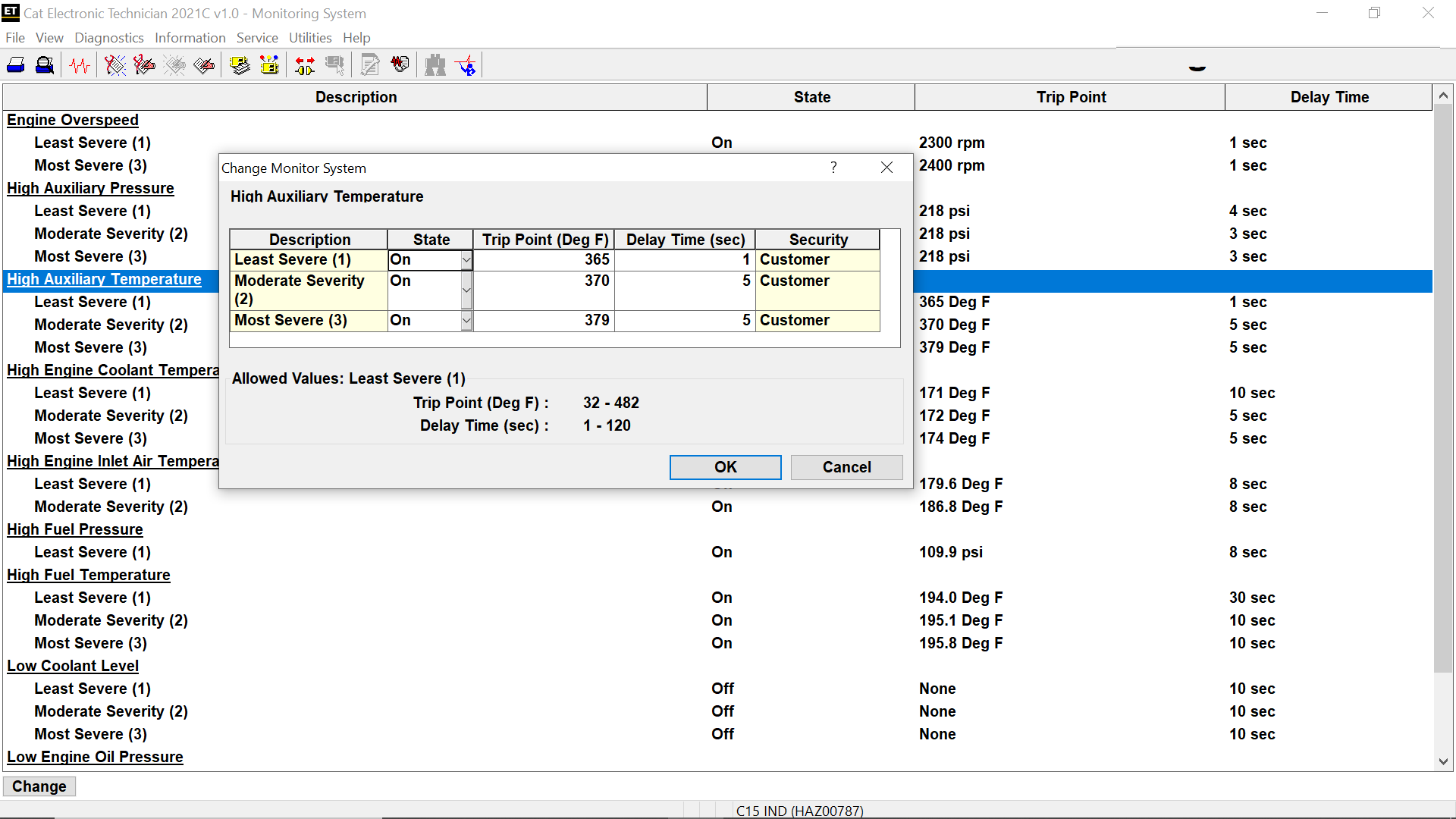

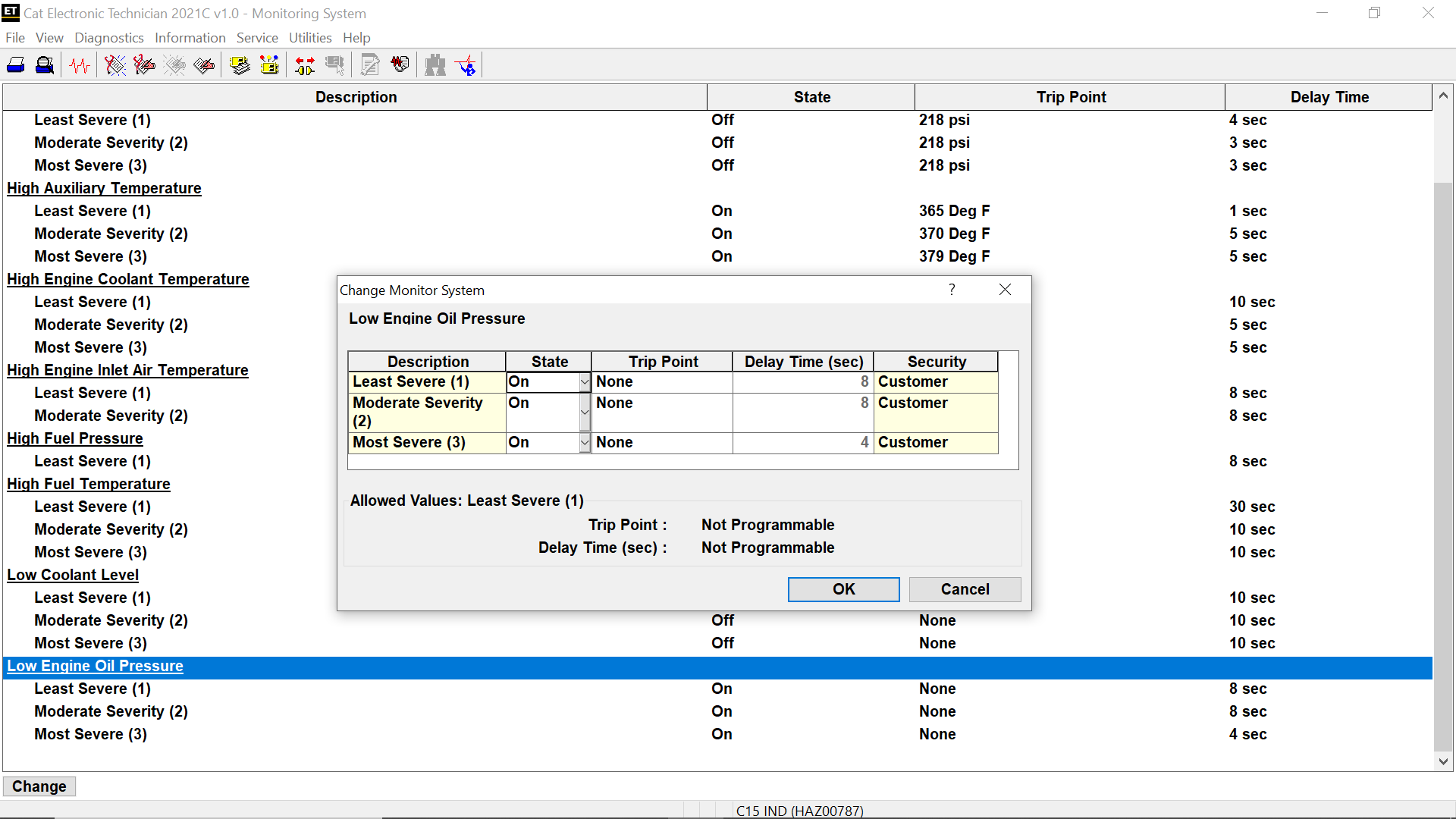

View the status of a group of parameters (temperatures, pressures, etc.) simultaneously

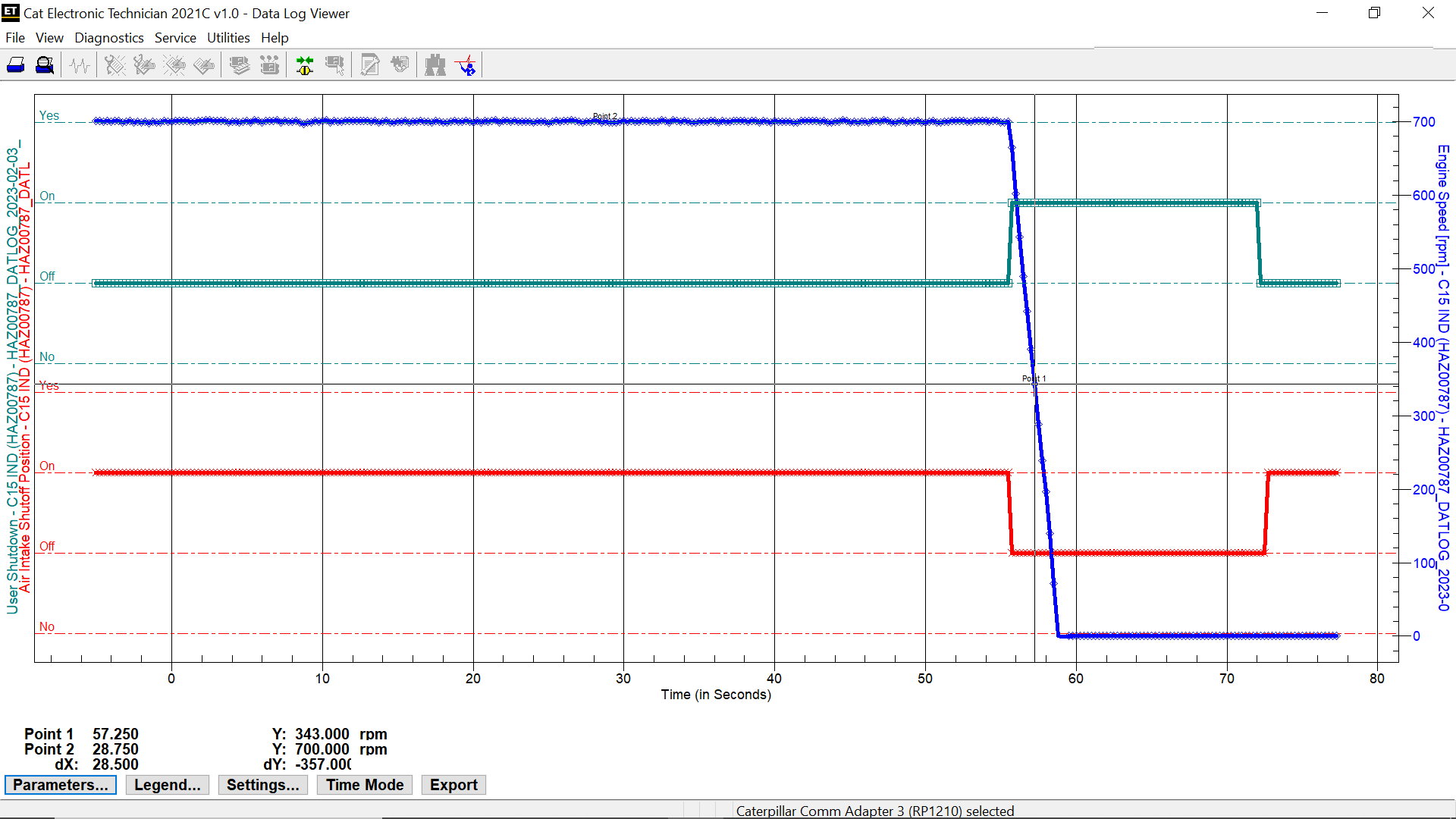

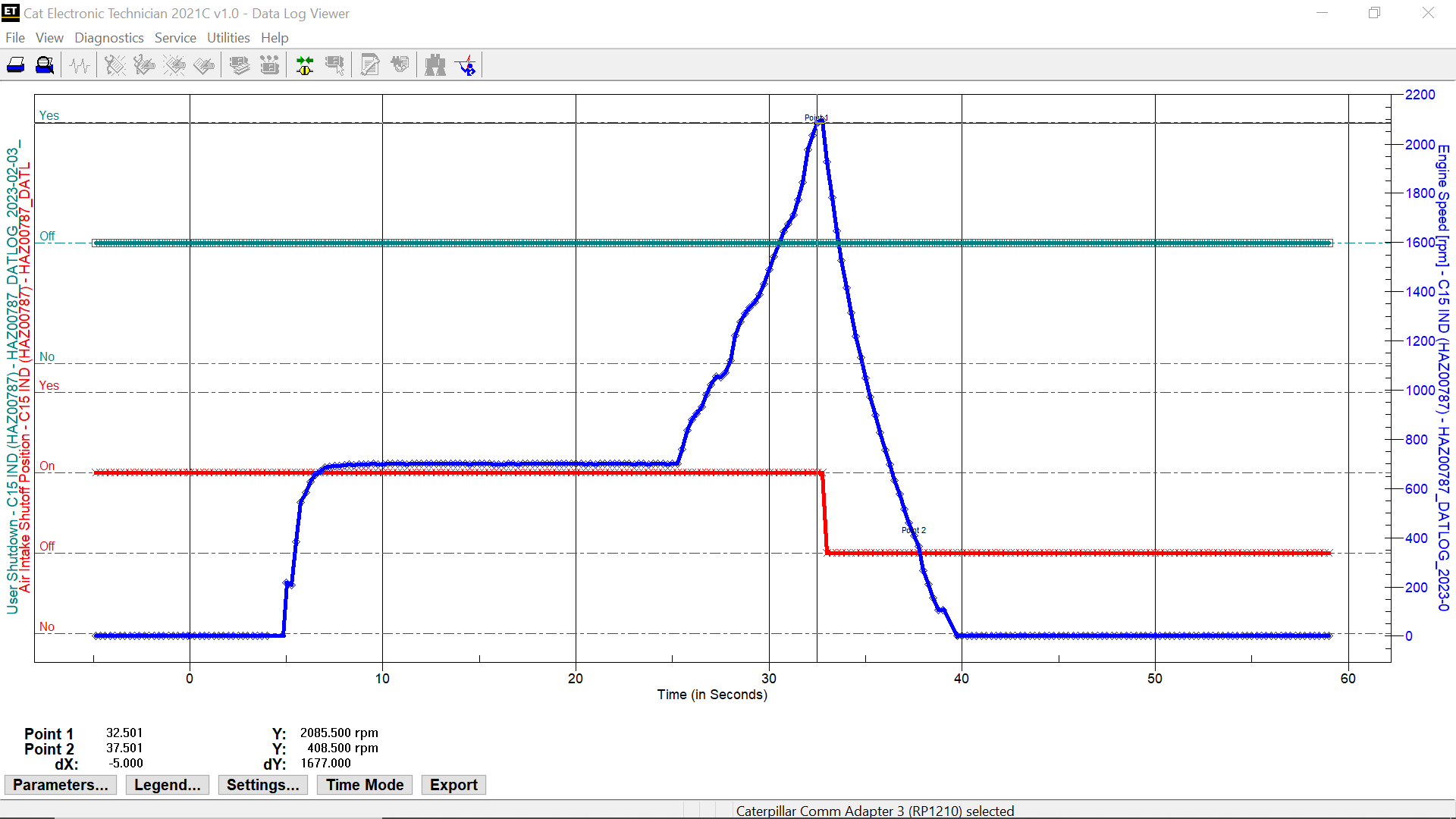

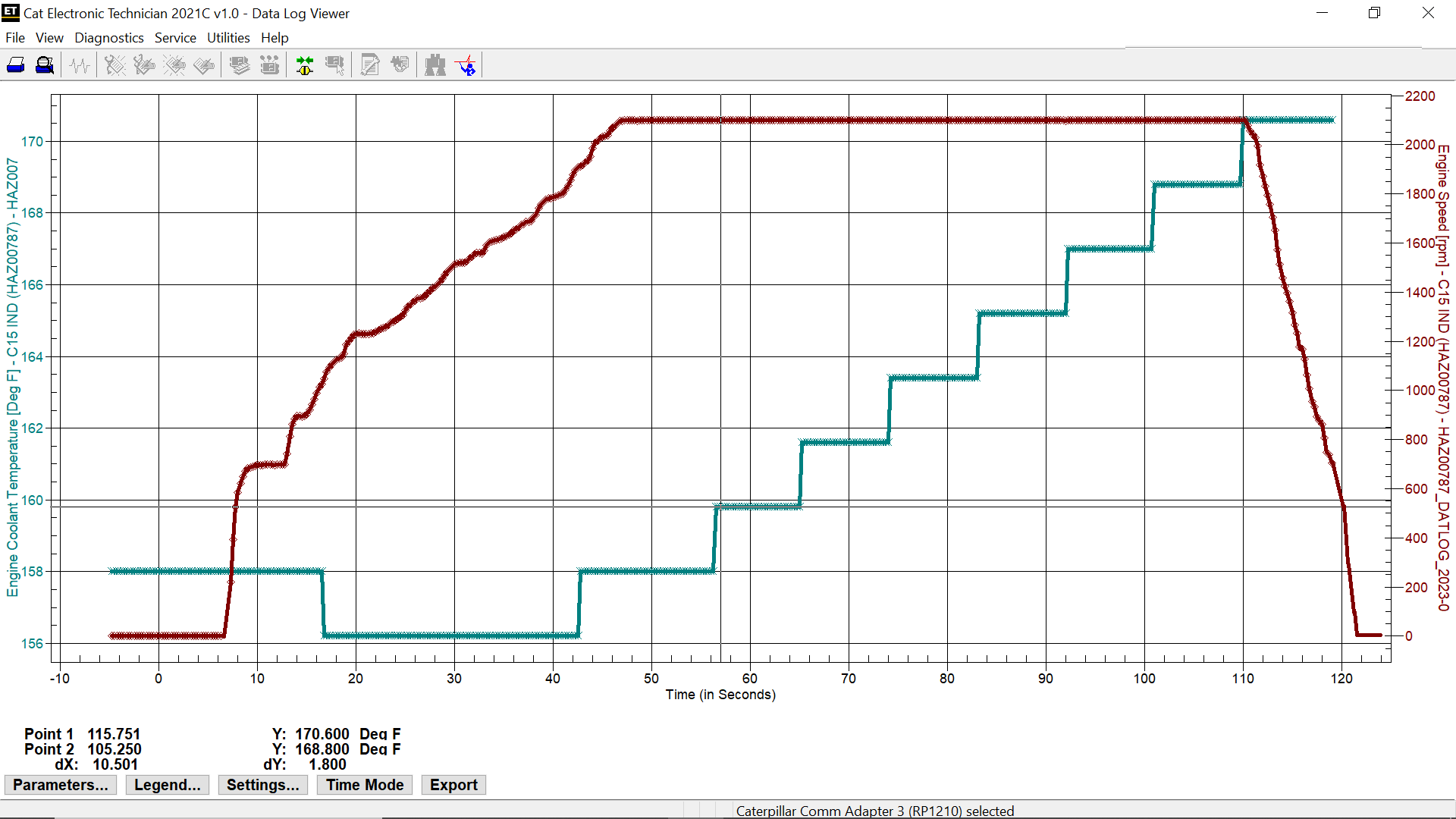

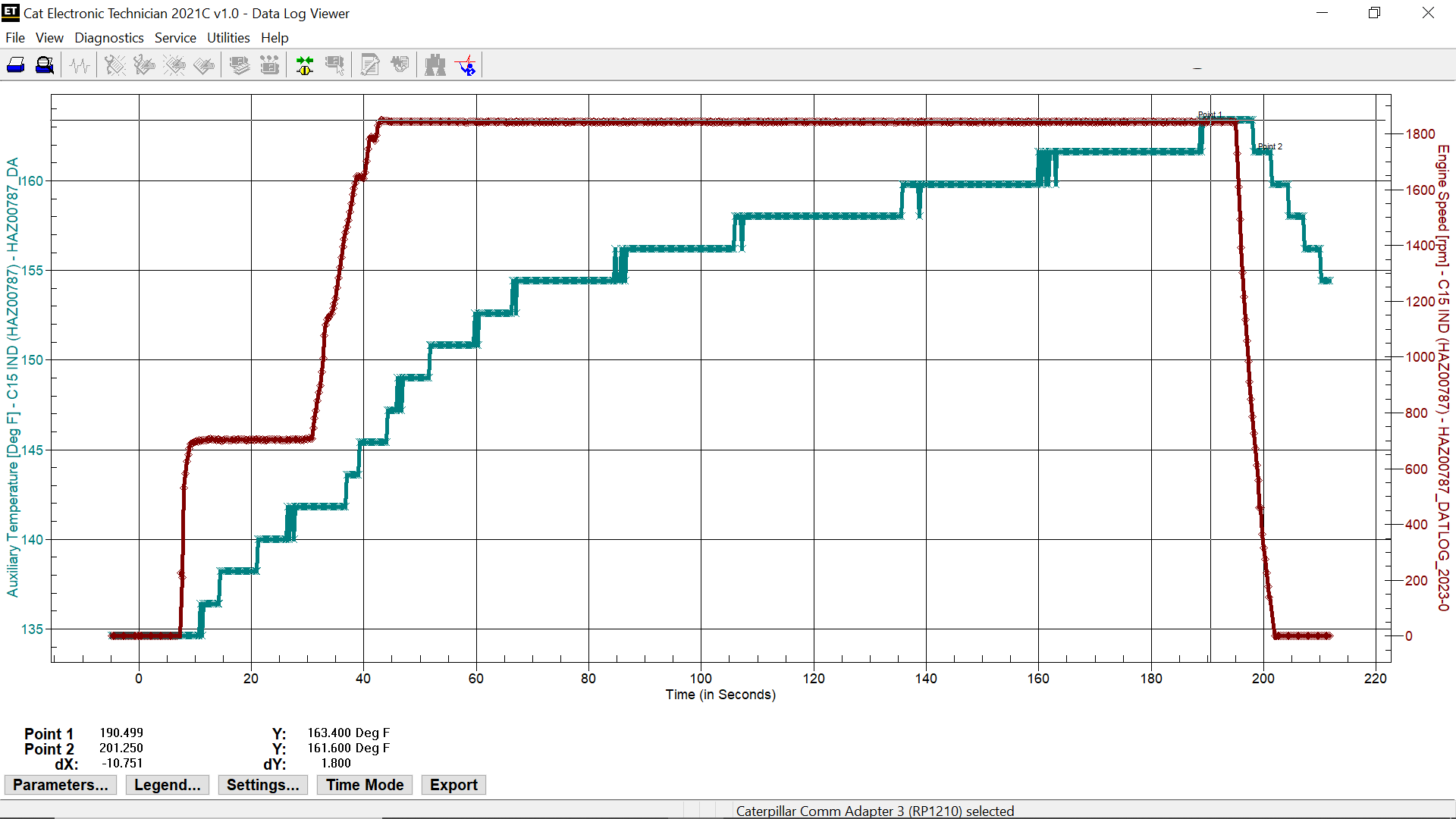

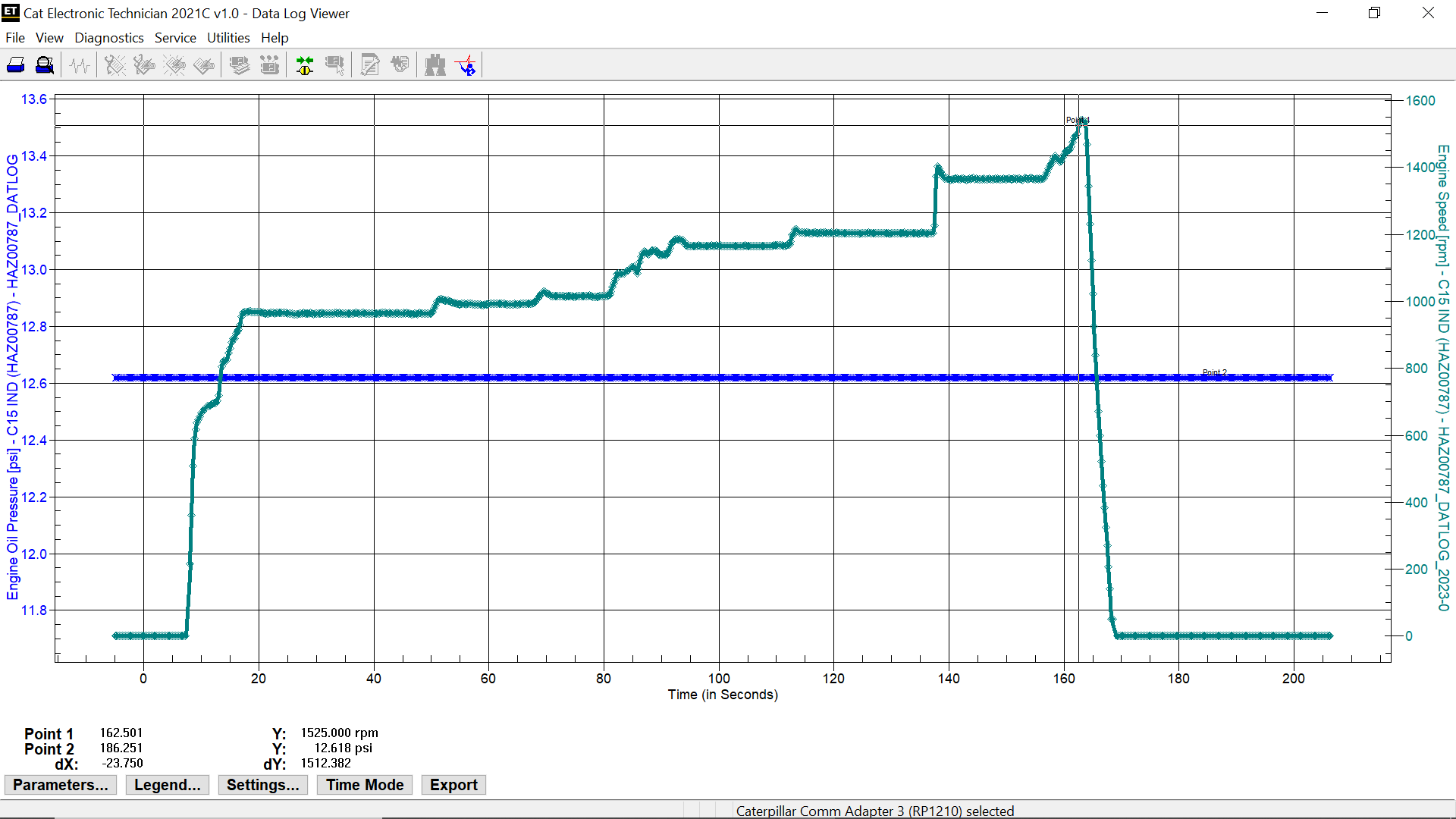

Record and log performance data

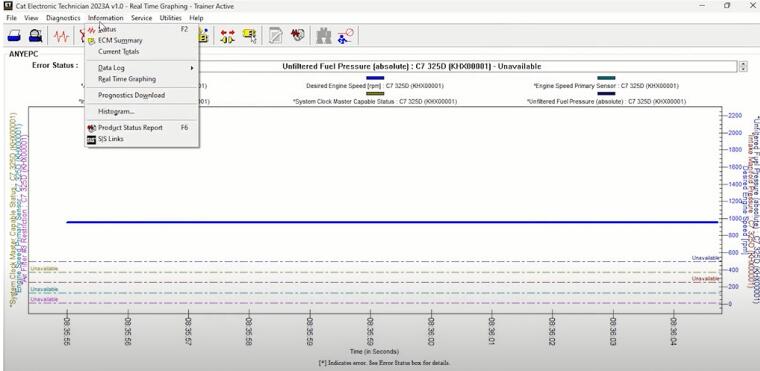

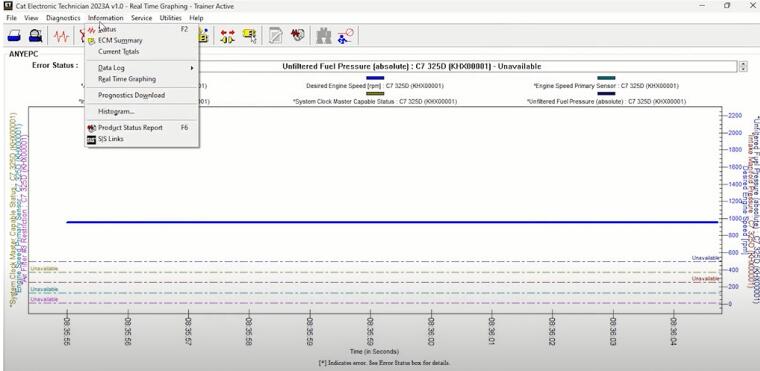

Graph a group of status parameters

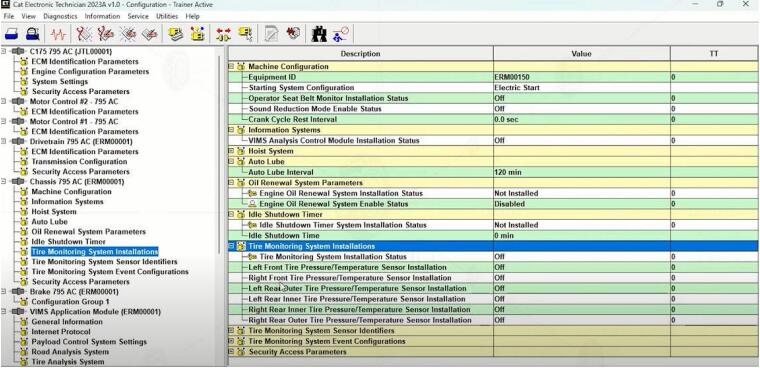

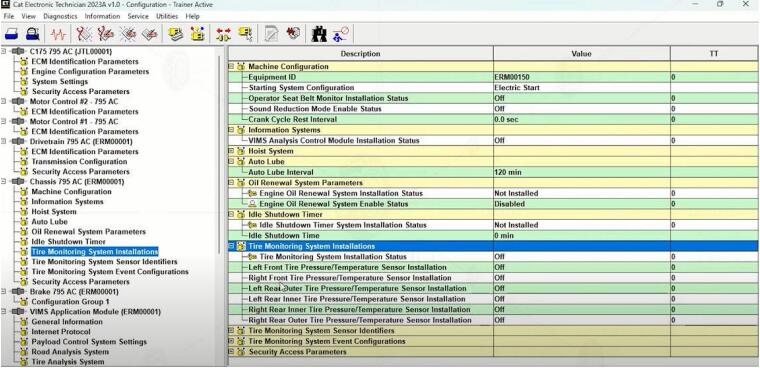

View the current configuration of an ECM

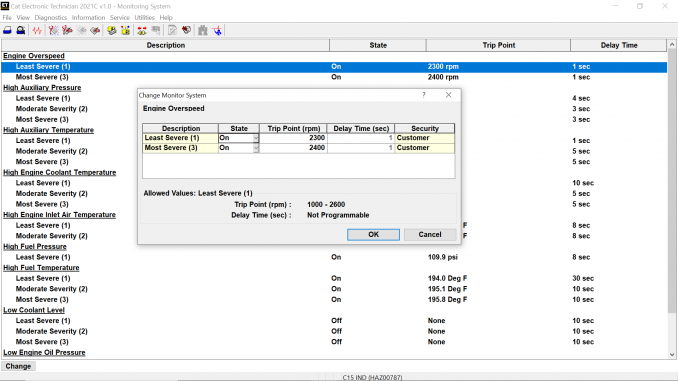

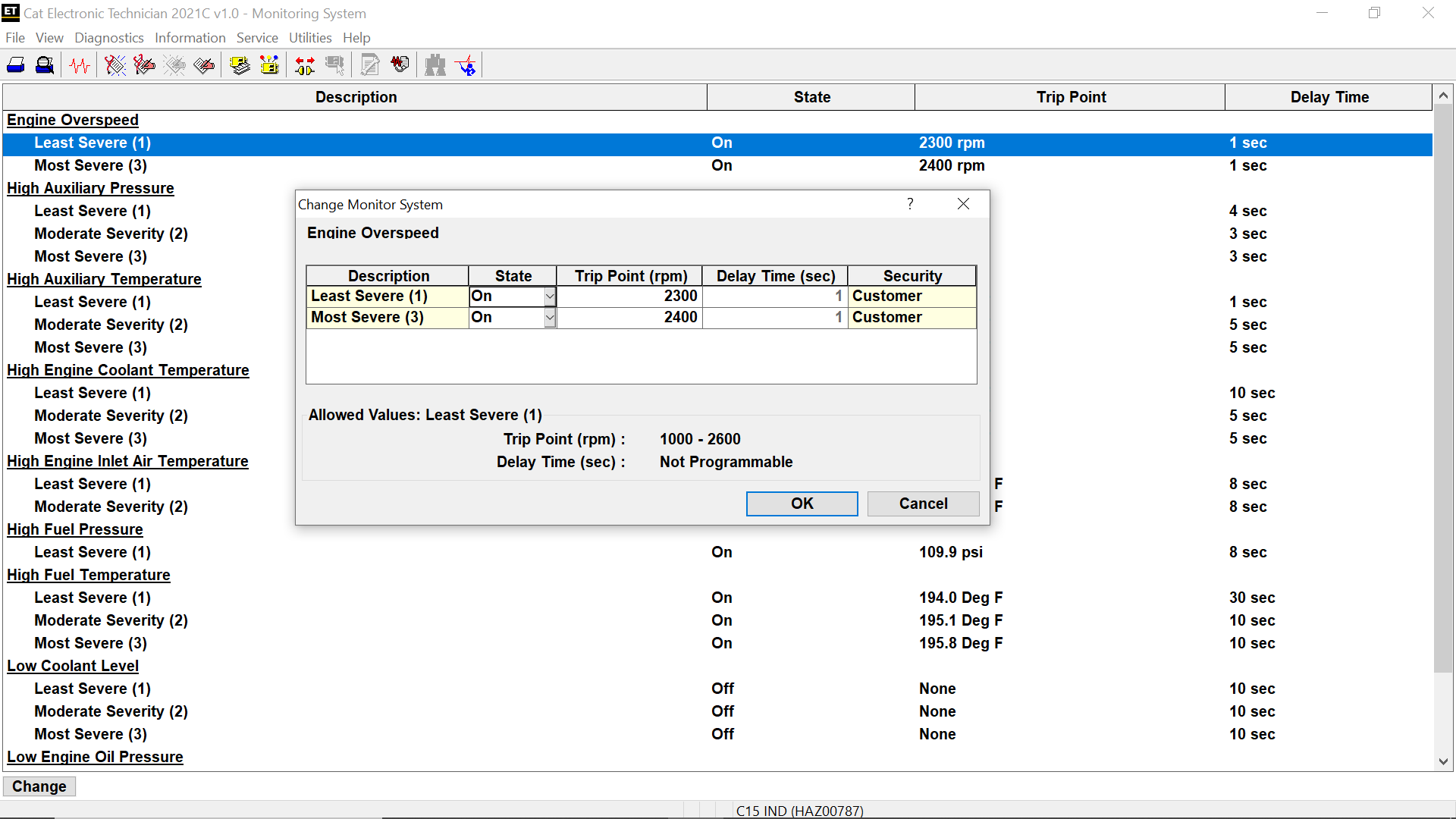

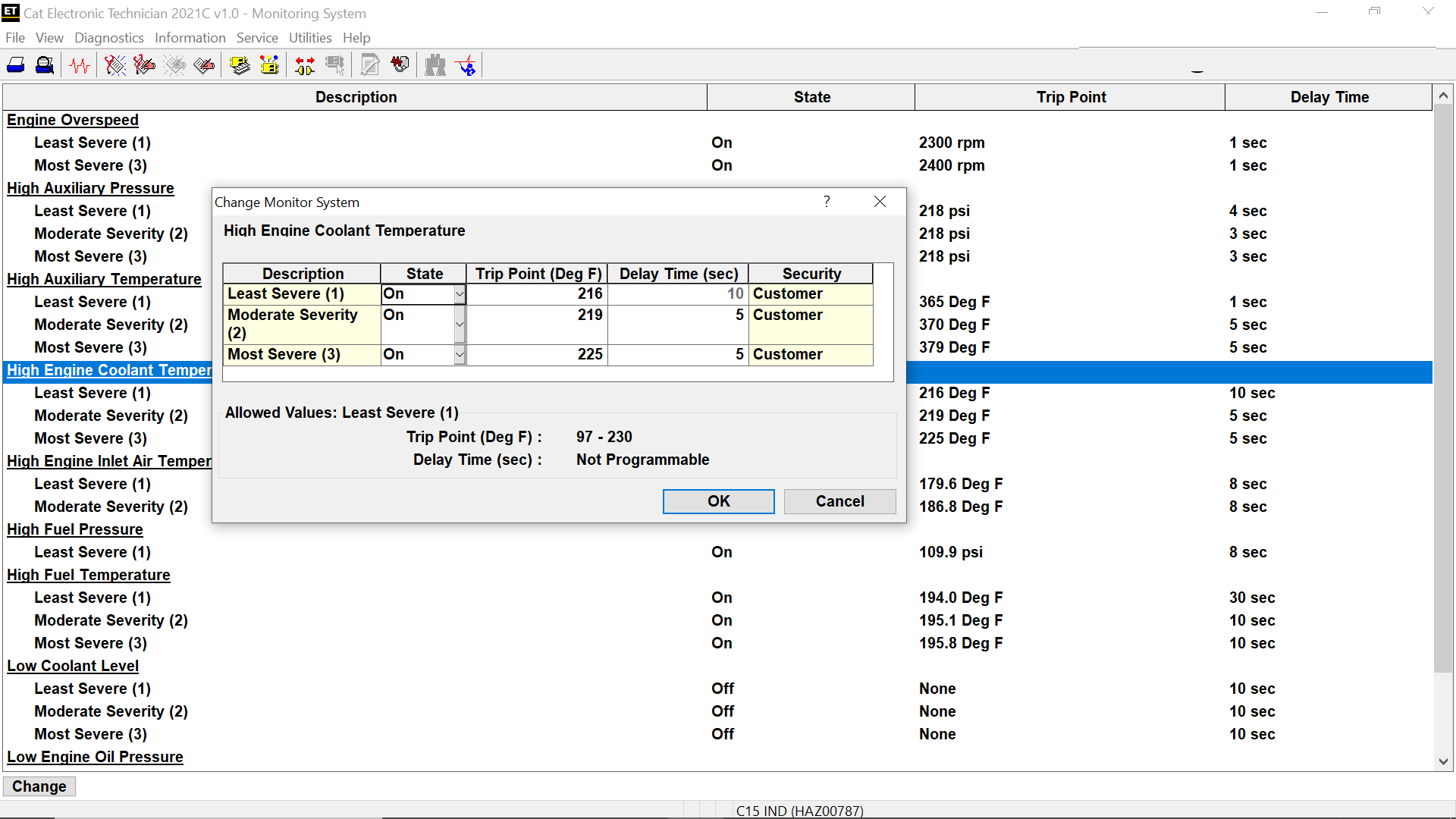

Change ECM configurations

Perform diagnostic tests

Perform calibrations

Print reports and diagnostic results

For some machine and engine products, additional functionality has been included with the service tool program

Caterpillar ET 2023A (replaces CAT ET 2022A, 2021A,2019C) Electronic Technician Diagnostic Software

Brand: Caterpillar

Region: WorldWide

Language: English, Chinese, Danish, French, German, Italian, Japanese, Portuguese, Russian, Spanish

Compatible OS: Windows 7 32 bit, Windows 7 64 bit, Windows 8/8.1 32 bit, Windows 8/8.1 64 bit, Windows 10 32 bit, Windows 10 64 bit

Publication date: 03.2023 year

Latest Caterpillar ET 2023A Software to work with CAT/CAT3 Truck Scanner

With one free activation, can send software online

PC, Communication Hardware, and Cable Requirements

To run the service tool, the next PC, communication hardware, and cable requirements must be met. NOTE: The minimum PC Configurations should not be used as a standard when buying new personal computers for service tool purposes. If the existing equipment meets these minimum requirements, it will run the service tool.

PC Requirements

Recommended Configurations

PC containing a 2.0 GHz dual-core processor

3GB RAM

3GB of the available hard disk drive

DVD-ROM drive (optionally)

15.4-inch XGA Screen (1280×1024 compatible)

Microsoft Windows™ 7 Professional or Windows 8 Professional, Windows 10 Professional (Not tested with Home Edition) (Note: Windows 8 RT is not supported)

RS232 port with 16550AF UART or compatible (for use with Comm Adapter II)

USB 1.1 or 2.0 port (for use with Comm Adapter 3)

Ethernet RJ45 connector

Built-in pointing device or mouse

For security purposes, Microsoft Internet Explorer version 11 or newer or Microsoft Edge is recommended.

Note: The most recent version of Microsoft Internet Explorer may not be validated to work with the service tool.

Caterpillar electronic technician 2021A with WinFlash future is an updated version of the caterpillar dealer diagnostic software that can help technicians to diagnose existing and potential problems with their electronically controlled Caterpillar Engines and Machines.

To get the vehicle information the Cat ET software must be connected to the Electronic Control Module (ECM). For this purpose, you need a suitable diagnostic link adapter (DLA), for instance, Genuine CAT Comm Adapter III .

The laptops with ARM CPUs (Snapdragon 8cx, Microsft SQ1, etc) type are not supported!

Microsoft ended extended support for Windows 7 as of January 2020. The CAT ET service tool no longer supports Windows 7 as of the 2020B release. The installation is still possible, but we’re not able to guarantee the stable work of 2020B or later versions.

The list of supported CAT machines and engines can be found below:

Engines:

Electric Power

Electric Power Generation

Industrial

Marine Power Systems

Oil and Gas

Machines:

Articulated Trucks

Asphalt Pavers

Backhoe Loaders

Cold Planers

Compactors

Dozers

Drills

Excavators

Feller Bunchers

Forest Machines

Forwarders

Harvesters

Hydraulic Mining Shovels

Knuckleboom Loaders

Material Handlers

Motor Graders

Off-Highway Trucks

Pipelayers

Road Reclaimers

Site Prep Tractors

Skid Steer and Compact Track Loaders

Skidders

Telehandlers

Track Loaders

Underground – Hard Rock

Underground – Longwall

Underground – Room and Pillar

Utility Vehicles

Wheel Dozers

Wheel Excavators

Wheel Loaders

Wheel Tractor-Scrapers

What’s New – 2022A

Microsoft® Windows™ 11 Compatibility

Service tool testing has been performed and the service tool is compatible with Windows 11.

ECM File Replacement Compare Feature

The service tool now has an ECM Replacement File Compare feature for troubleshooting purposes. This feature allows the user to compare one ECM replacement file with another from within the ECM Replacement feature screen. The feature will highlight the differences between the selected files as a whole or the user may select the “only show differences” checkbox.

Configuration Group Headings on ECM Replacement Feature

In order to help the user find ECM replacement configuration items easier, configuration items in the ECM Replacement, Fleet Configuration, and Product ECM features are now grouped under their group sub-headings, as is done in the main configuration feature.

What’s New – 2021A

No significant new features or feature enhancements

What’s New – 2020C

No significant new features or feature enhancements

What’s New – 2020B

Trainer Update – 299D3

The 299D3 Skid Steer Loader has been added to the Trainer application.

What’s New – 2020A

Product Status Report Updates

The Product Status Report has been updated to include throttle configuration information.

Built-in Factory Password Generator

The experimental feature allows you to decode (18-Bit passwords not supported) factory passwords

What’s New – 2019C

Indication of Selected Communications Adapter

The service tool now displays the selected communications adapter when the service tool is disconnected. The adapter name is displayed in the status area at the bottom right of the service tool

End of Support for Windows 7

Microsoft is ending extended support for Windows 7 as of January 2020. The service tool will be ending support for Windows 7 as of the 2020A release.

What’s New – 2019B

Automatic Product Status Report (PSR) Upload

The service tool includes a new tool that automatically uploads Product Status Reports. The tool scans for newly generated Product Status Reports and uploads them when an internet connection is available. The default is that automatic report uploading is enabled. The Preferences dialog has an option to disable the tool.

What’s New – 2019A

ECM Naming Changes

Certain ECMs connect to the service tool over two data links at the same time. The service tool shows a message popup when the ECM is only detected on one link. The service tool has been changed to add the text **INCOMPLETE** in the ECM name when the connection is incomplete. Service tool features that display a connection icon also use a new icon for an incomplete connection.

What’s New – 2018C

No significant new features or feature enhancements

What’s New – 2018B

CEOS Fleet Configuration File TOP

A CEOS (Customer Electronic Option Selection) Fleet Configuration File can be created/modified for an engine using the Service Tool. This is available in connected and disconnected mode.

Error When Launching Service Tool

There is a Microsoft issue with upgrading libraries during an installation involving certain versions of the C++ redistributable. After a successful service tool installation, when trying to run the service tool for the first time, one of the following errors may occasionally appear: “The entry point could not be located in api-ms-win-crt-runtime” or “The program can’t start because mfc140u.dll is missing from your computer.” If either of these messages is displayed, please let us know and we will send you to step by step troubleshooting guide. This procedure requires administrator rights.

Service Tool License Corruption Issues with Windows 10 Updates

Windows 10 updates 1709 and 1803 will corrupt service tool licenses. Future Window 10 updates may do the same

If either of the license error messages is displayed, please let us know and we will send you to step by step troubleshooting guide.

What’s New – 2018A

Trainer Update – 988K XE Wheel Loader

The 988K XE Wheel Loader has been added to the Trainer application.

What’s New – 2017C

Preferences Option to Save a Product Status Report to PDF

The Preferences dialog for the Product Status Report has changed. The dialog contains a new checkbox to automatically save a Product Status Report as a PDF file when the report is created. The service tool will continue to automatically save Product Status Reports as an XML file.

What’s New – 2017B

Product Status Report Updates

The Product Status Report has been updated to include certain history features supported by the ECM, such as the after-treatment Regeneration History and the Service Test History.

Winflash Screen Update

The screen for the Winflash feature has been updated. A new Expand All button opens all sections of the screen to show all details for ECMs detected by WinFlash. A new Collapse All button hides all sections of the screen, except for header rows showing detected ECM names.

Communication Hardware

Caterpillar Communication Adapter III Kit

Configuring Cat Electronic Technician to use the Communication Adapter 3

For Cat Electronic Technician to work with the Communication Adapter 3, the settings must be changed to select the Communication Adapter 3 as the Communication Interface Device:

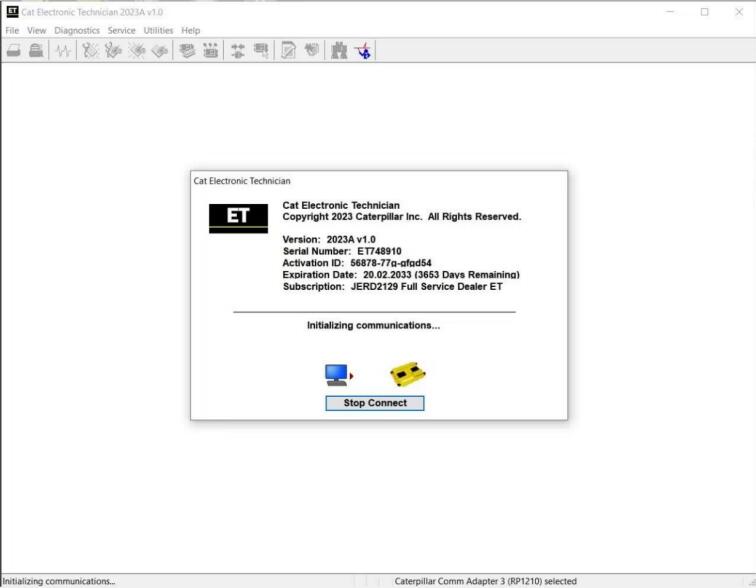

Step 1 Start Cat Electronic Technician.

Step 2 Click the Stop Connect button when it appears.

Step 3 Select the utility menu.

Step 4 Choose “Preferences > Modify…”.

Step 5 Select the Communications tab.

Step 6 Select Cat Comm Adapter 3 (RP1210) and click OK.

NOTE: Because a growing number of products require multiple data link service, the “Enable Dual Datalink Service” checkbox has been pre-selected.

Servicing ECMs on more than one data link requires this checkbox to be enabled.

Failure to do this will result in undetected ECMs and reduced functionality.

Original Factory Caterpillar ET3 Adapter III Compare With OEM Caterpillar ET Diagnostic Adpater III

1. Original Factory CAT ET can use once pluged, no need install the USB drive, the software can automatic realize it for ET3 Adapter, and the machine can automatic weld the high quality Circuit board, quality will be more reliable.

2. The OEM Caterpillar ET Diagnostic Adapter III need use USB Drive to install, and need choose the COM Port, and in the software ET also need choose ET2 then can be used.