There are several benefits of hiring a CNC milling manufacturer. This company will ensure that your CNC milling projects meet the strict quality and production standards of the defense industry. As well as providing you with the necessary precision and speed, these companies will provide a wide range of advanced manufacturing solutions to meet your needs. Before choosing a CNC milling manufacturer, consider the following factors: Your budget, minimum order quantity, and the type of work you need to be done.

If you’re looking for an excellent CNC milling manufacturer, check out Okuma. They’re a Japanese company with over one thousand employees in over 70 countries. Their wide selection of CNC machines and diverse distribution networks have helped them establish themselves as a world-class company. During the design phase, you can use computer simulations to test materials and designs and determine which parts will require machining. Whether you need a complex part or a simple prototype, a CNC milling manufacturer will be able to help you.

Another benefit of CNC milling is their flexibility. They can work on any material and can perform a wide variety of operations. Depending on the type of project, a CNC milling manufacturer will have a machine to meet your needs. They should also have a wide selection of tools to accommodate your business’s needs. You can find a CNC milling manufacturer online or talk to a representative at your local machine shop. You can request a quote within 24 hours. If you’re unsure of what type of machine you need, contact a local CNC milling manufacturer for more information.

Once you’ve decided on a CNC milling manufacturer, it’s time to start choosing the right machine for your needs. First, you should know what type of material you’re going to use. A good CNC milling manufacturer will be able to offer you a wide range of materials and machine types. Secondly, a good CNC milling manufacturer will be able to provide you with a large number of replacement parts.

When choosing a CNC milling manufacturer, you should look for a company that offers a wide range of services and tools. It should offer a variety of CNC machine tools, including drilling, boring, and tapping. A CNC milling manufacturer should be able to give you a quote within 24 hours of contacting the company. This will make it easy to choose a CNC milling manufacturer. When it comes to quality, you should choose a CNC milling manufacturer that offers a variety of services and equipment.

When choosing a CNC milling manufacturer, you should also consider their service. An excellent manufacturer should offer a wide range of services, and you should be able to choose from a large selection of machines. For example, a CNC milling manufacturer with a large selection of drilling, boring, and tapping tools will be able to accommodate your needs. A CNC milling manufacturer with a wide product range will be the right partner for your organization.

A CNC milling manufacturer should offer a wide range of tools and services. It should offer a large number of machines for different applications. You should be able to find a CNC milling manufacturer near you by researching the internet and talking with a machine representative. You should be able to get a quote within 24 hours. There are numerous CNC milling manufacturers in your area. You should be able to find whichever one is closest to you.

A CNC milling manufacturer should have a wide range of tools and services. It should also have a large selection of machines. A CNC milling manufacturer should also have a wide range of tools. You should look for a CNC milling manufacturer with a large selection of tools. You can search online or speak with a machine representative to find a CNC-milling manufacturer in your area. They should be able to provide you with a quote for your project within 24 hours.

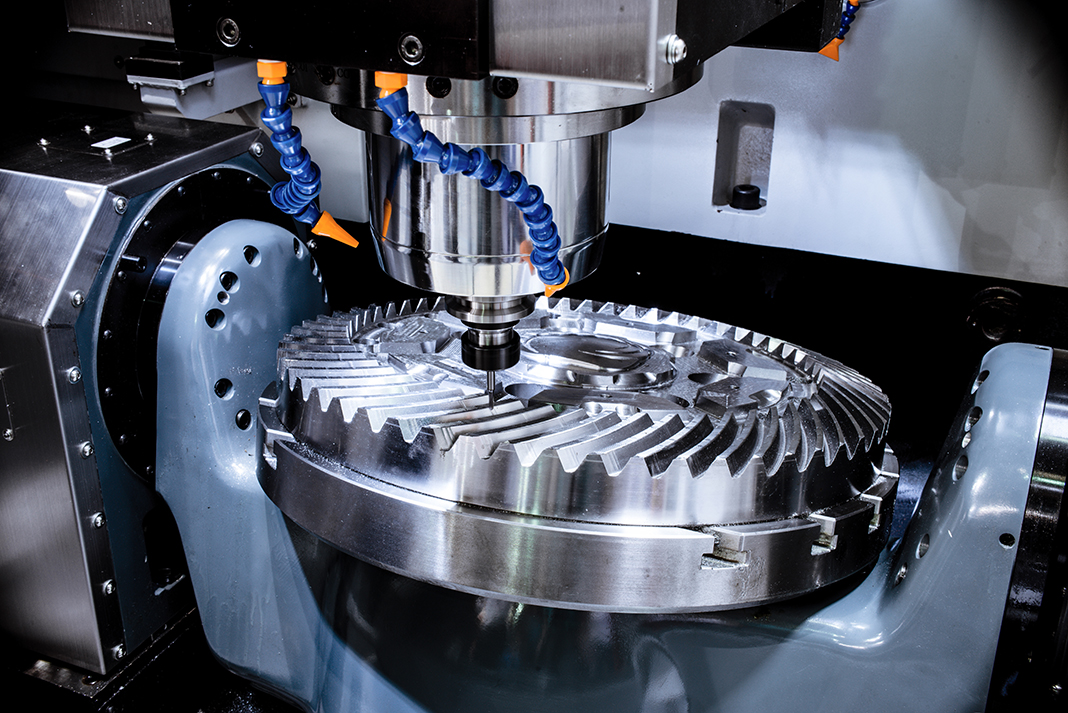

CNC milling manufacturers are able to produce intricate and complex parts for a wide range of industries. These CNC milling machines can be used to produce prototypes and high-quality components for final assembly. The process itself can be horizontal or vertical, depending on CAD requirements. Once the workpiece is inserted in the CNC machine, the milling tools are placed on the spindle. A CNC operator will then activate the program and start the job.