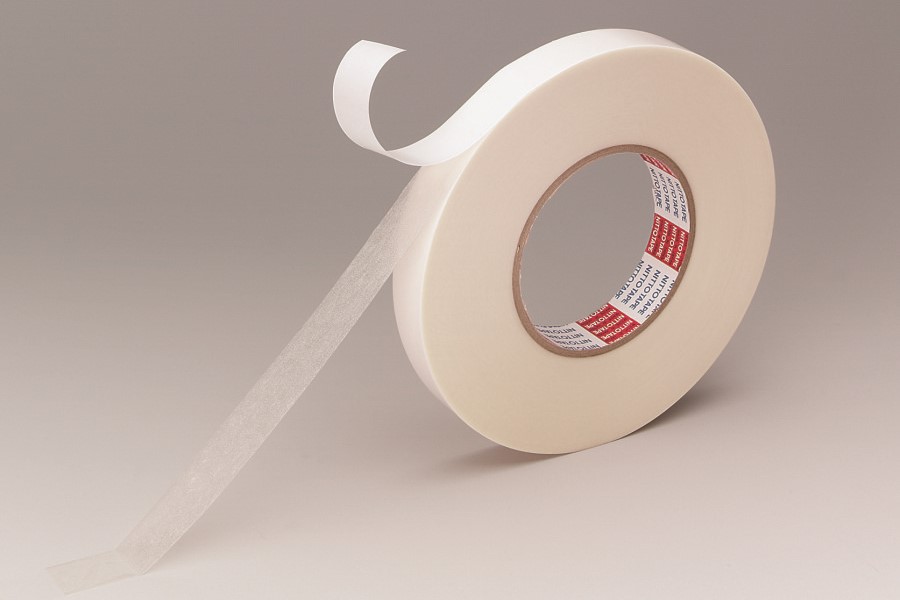

The Double-Sided Masking Tapes Market showcased remarkable sustainability, reaching a valuation of 1536.52 million USD. Projections indicate a continued upward trajectory, with an anticipated value of 2130.1 million USD by 2032, reflecting a compound annual growth rate (CAGR) of 3.7%.The double-sided masking tapes market has seen substantial growth in recent years, driven by its extensive application across various industries such as automotive, construction, electronics, and healthcare. These tapes are known for their strong adhesive properties, flexibility, and ability to provide a clean, finished appearance without the need for mechanical fasteners. This article delves into the market dynamics, key drivers, challenges, and future prospects of the double-sided masking tapes market.

Browse the full report at https://www.credenceresearch.com/report/double-sided-masking-tapes-market

Market Dynamics and Key Drivers

1. Industrial Applications: The primary driver of the double-sided masking tapes market is their widespread use in industrial applications. In the automotive industry, these tapes are used for mounting parts, bonding materials, and ensuring vibration dampening. Their role in providing a clean, precise finish without the use of visible fasteners makes them indispensable.

2. Construction and Building: In construction, double-sided masking tapes are utilized for bonding insulation materials, mounting mirrors, and securing carpets and floor coverings. Their ability to provide a strong bond and maintain aesthetic integrity is highly valued.

3. Electronics and Electrical: The electronics industry benefits from these tapes for mounting components, bonding displays, and managing thermal insulation. The precision and reliability of double-sided masking tapes are critical in manufacturing processes where accuracy and performance are paramount.

4. Healthcare Applications: In the healthcare sector, these tapes are used for securing medical devices, wound care dressings, and adhering medical tapes to the skin. Their hypoallergenic properties and strong adhesion without causing irritation make them suitable for medical applications.

Market Segmentation

The double-sided masking tapes market is segmented based on adhesive type, backing material, end-use industry, and geography.

1. Adhesive Type: The market includes tapes with different adhesive types such as acrylic, rubber, and silicone. Acrylic adhesives are favored for their strong bonding and durability, while rubber adhesives are known for their immediate tackiness and silicone for their temperature resistance.

2. Backing Material: Common backing materials include paper, foam, film, and cloth. Each material offers distinct advantages, with paper being flexible and easily tearable, foam providing cushioning, film offering durability, and cloth ensuring high tensile strength.

3. End-Use Industry: The major end-use industries are automotive, construction, electronics, and healthcare, each utilizing these tapes for specific applications.

4. Geographical Insights: The market is geographically diverse, with significant growth observed in North America, Europe, Asia-Pacific, and Latin America. Asia-Pacific, particularly China and India, is expected to witness robust growth due to rapid industrialization and expanding automotive and electronics manufacturing sectors.

Challenges

Despite the growth prospects, the double-sided masking tapes market faces certain challenges. The volatility in raw material prices can impact production costs and profit margins. Additionally, the availability of alternative bonding solutions such as liquid adhesives and mechanical fasteners poses a competitive threat. Environmental regulations regarding the use of certain chemicals in adhesives can also affect market dynamics.

Future Prospects

The future of the double-sided masking tapes market looks promising, with several trends driving growth:

1. Technological Advancements: Innovations in adhesive technology are expected to enhance the performance characteristics of double-sided masking tapes, making them more versatile and efficient.

2. Eco-Friendly Products: There is a growing trend towards sustainable and eco-friendly products. Manufacturers are increasingly focusing on developing tapes with biodegradable materials and solvent-free adhesives.

3. Expanding Applications: New applications in emerging industries such as renewable energy, aerospace, and consumer electronics are anticipated to create additional demand.

4. Customization and Specialization: Customization of tapes to meet specific industry requirements and the development of specialized tapes for niche applications will provide a competitive edge to manufacturers.

Key Players

- 3M

- Tesa SE

- Nitto Denko Corporation

- Avery Dennison Corporation

- Shurtape Technologies, LLC

- Scapa Group plc

- Intertape Polymer Group, Inc.

- Saint-Gobain Performance Plastics Corporation

- Lohmann GmbH & Co. KG

- Berry Global, Inc.

Market Segmentation

By Resin Type:

- Silicone

- Rubber

- Acrylic

- Others

By Technology:

- Solvent-based

- Hot-melt-based

- Water Based

By Tape-Backing Material:

- Film-backed

- Foam-backed

- Paper-/Tissue-backed

- Unsupported-/Transfer-backed

- Others

By End-Use Industry:

- Paper and Printing

- Building and Construction

- Electrical & Electronics

- Automotive

- Others

By Region

- North America

- US

- Canada

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- Australia

- Rest of Asia Pacific

- Latin America

- Middle East & Africa

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: sales@credenceresearch.com