The epoxy adhesives market has exhibited substantial growth over the past decade, with a notable trajectory from 2023 to 2032. In 2023, the market valuation stood at USD 8713 million, and by 2032, it surged to USD 14972.29 million, reflecting a commendable compound annual growth rate (CAGR) of 6.2%.Epoxy adhesives are a crucial segment of the adhesives industry, known for their high strength, durability, and resistance to environmental factors. These adhesives are widely used in various industries, including automotive, construction, aerospace, and electronics, due to their superior bonding capabilities. This article explores the current state of the epoxy adhesives market, key trends, growth drivers, challenges, and future prospects.

Browse the full report at https://www.credenceresearch.com/report/epoxy-adhesives-market

Market Overview

The global epoxy adhesives market has witnessed significant growth over the past decade. According to recent reports, the market was valued at approximately USD 7 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of around 6% from 2024 to 2030. This growth is driven by increasing demand from end-use industries, technological advancements, and rising infrastructure development activities worldwide.

Key Trends and Drivers

1. Growing Automotive Industry: The automotive sector is one of the largest consumers of epoxy adhesives. These adhesives are used in various applications, including structural bonding, panel bonding, and laminating. The shift towards lightweight vehicles to improve fuel efficiency has further boosted the demand for epoxy adhesives, as they help in reducing the weight of vehicles without compromising on strength.

2. Expansion of Construction Activities: The construction industry extensively uses epoxy adhesives for applications such as concrete repair, flooring, and structural bonding. The rising urbanization and increasing infrastructure projects, especially in emerging economies, are major factors driving the demand for epoxy adhesives in this sector.

3. Advancements in Aerospace Industry: Epoxy adhesives play a crucial role in the aerospace industry due to their high strength-to-weight ratio and resistance to harsh environmental conditions. With the growing demand for commercial and military aircraft, the need for advanced adhesives has surged, propelling the epoxy adhesives market.

4. Technological Innovations: Continuous research and development activities have led to the introduction of advanced epoxy adhesive formulations. These innovations aim to enhance the performance characteristics of adhesives, such as improved curing time, higher bond strength, and better resistance to chemicals and temperature variations.

Challenges

Despite the promising growth prospects, the epoxy adhesives market faces several challenges.

1. Volatility in Raw Material Prices: The primary raw materials used in epoxy adhesives are derived from petrochemicals. Fluctuations in crude oil prices can lead to instability in the cost of these raw materials, affecting the overall pricing of epoxy adhesives.

2. Environmental and Regulatory Concerns: The production and disposal of epoxy adhesives can have environmental impacts. Stringent regulations regarding volatile organic compounds (VOCs) emissions and the use of hazardous chemicals pose challenges for manufacturers. There is a growing need for eco-friendly and sustainable adhesive solutions to meet regulatory requirements and consumer preferences.

3. Competition from Alternative Adhesives: While epoxy adhesives offer numerous advantages, they face competition from other adhesive types, such as polyurethane and acrylic adhesives. These alternatives may offer specific benefits in certain applications, leading to a competitive market landscape.

Regional Insights

The epoxy adhesives market exhibits varying trends across different regions.

1. North America: The region holds a significant share of the market, driven by strong demand from the automotive and aerospace industries. Technological advancements and a focus on sustainable adhesive solutions further support market growth in this region.

2. Europe: Europe is another prominent market for epoxy adhesives, with substantial demand from the automotive, construction, and electronics sectors. Stringent environmental regulations in the region are pushing manufacturers towards the development of low-VOC and eco-friendly adhesives.

3. Asia-Pacific: This region is expected to witness the highest growth rate during the forecast period. Rapid industrialization, urbanization, and infrastructure development in countries like China and India are major factors driving the demand for epoxy adhesives. The expanding automotive and electronics industries also contribute to market growth in this region.

Future Prospects

The future of the epoxy adhesives market looks promising, with continuous advancements and growing applications across various industries. Manufacturers are focusing on developing innovative, sustainable, and high-performance adhesive solutions to meet the evolving demands of end-users. Additionally, the increasing trend towards lightweight materials and the growth of the renewable energy sector are expected to create new opportunities for epoxy adhesives.

Key Players

- Henkel AG & Co. KGaA

- 3M Company

- Sika AG

- Huntsman Corporation

- B. Fuller Company

- Dow Inc.

- Ashland Global Holdings, Inc.

- LORD Corporation

- Permabond Engineering Adhesives

- Pidilite Industries Limited

Segments

By Type:

- One-component

- Two-component

- Others

By End-Use Industry:

- Building and Construction

- Transportation

- Marine

- Automotive

- Wind Energy

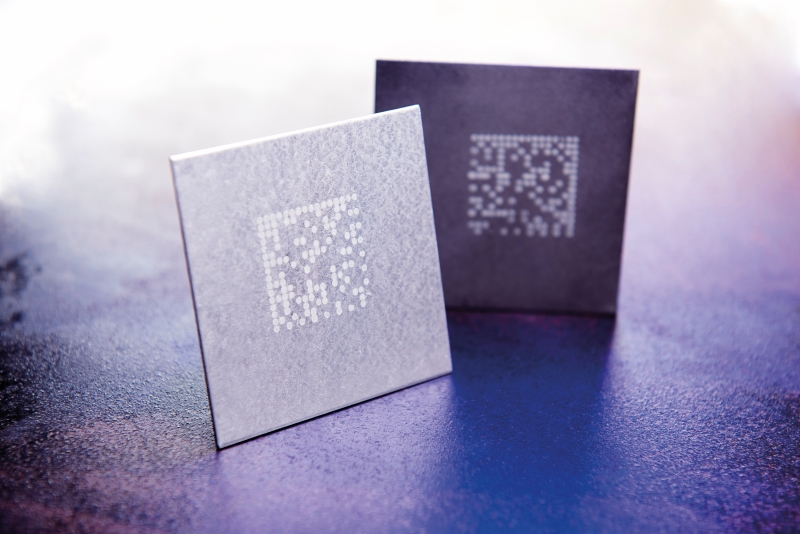

- Electrical & Electronics

- Others

By Region

- North America

- The US.

- Canada

- Mexico

- Europe

- Germany

- France

- The U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: sales@credenceresearch.com