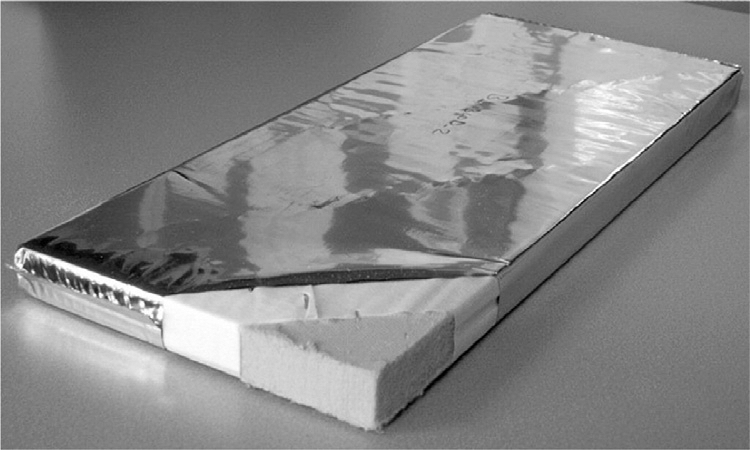

The global vacuum insulation panel market was valued at $7.9 billion, with a compound annual growth rate (CAGR) of 4.50%. This growth trajectory is expected to continue, with market size projected to reach $12.3 billion by 2032.The Vacuum Insulation Panel (VIP) market is witnessing a remarkable growth trajectory, driven by the increasing demand for energy-efficient solutions across various industries. VIPs are a type of thermal insulation that offers superior insulation performance compared to traditional materials. They consist of a core material enclosed in a vacuum-sealed barrier, significantly reducing heat transfer. This article delves into the current trends, key drivers, challenges, and future prospects of the VIP market.

Browse the full report at https://www.credenceresearch.com/report/vacuum-insulation-panel-market

Market Overview

The global VIP market has been expanding rapidly, with a compound annual growth rate (CAGR) projected to be in the high single digits over the next decade. This growth is underpinned by the increasing awareness of energy conservation, stringent building regulations, and the rising adoption of green building practices. VIPs are extensively used in construction, refrigeration, logistics, and packaging industries due to their high thermal resistance and space-saving attributes.

Key Drivers

1. Energy Efficiency and Sustainability: One of the primary drivers of the VIP market is the growing emphasis on energy efficiency and sustainability. Governments worldwide are implementing stricter regulations to reduce carbon emissions and improve energy performance in buildings. VIPs offer an effective solution by providing high thermal insulation with minimal thickness, thus conserving energy and reducing greenhouse gas emissions.

2. Construction Industry Boom: The construction sector is a major consumer of VIPs, especially in regions experiencing rapid urbanization and infrastructure development. In Europe and North America, the focus on energy-efficient buildings and retrofitting old structures to meet new energy standards is boosting the demand for VIPs.

3. Refrigeration and Cold Chain Logistics: In the refrigeration sector, VIPs are used to enhance the insulation of refrigerators, freezers, and cold storage units. The cold chain logistics industry, crucial for transporting perishable goods and pharmaceuticals, also relies heavily on VIPs to maintain low temperatures and ensure product integrity during transit.

4. Technological Advancements: Advances in materials science and manufacturing processes are leading to the development of more efficient and cost-effective VIPs. Innovations such as the incorporation of advanced core materials like silica, fiberglass, and aerogel are enhancing the performance and durability of VIPs.

Challenges

Despite the promising growth prospects, the VIP market faces several challenges:

1. High Initial Costs: VIPs are more expensive than traditional insulation materials, which can deter their adoption, especially in cost-sensitive markets. The high initial investment required for VIPs is a significant barrier, although this is offset by long-term energy savings.

2. Durability and Lifespan: The performance of VIPs can degrade over time due to punctures or breaches in the vacuum seal. Ensuring the longevity and reliability of VIPs remains a critical challenge that manufacturers need to address.

3. Limited Awareness and Expertise: There is a need for greater awareness and expertise regarding the application and benefits of VIPs. Many architects, builders, and consumers are not fully informed about the advantages of VIPs, which hampers their widespread adoption.

Future Prospects

The future of the VIP market looks promising, with several trends set to shape its trajectory:

1. Integration with Smart Technologies: The integration of VIPs with smart building technologies and IoT (Internet of Things) is expected to drive their adoption. Smart insulation systems that can monitor and adjust thermal performance in real-time are on the horizon, offering enhanced energy efficiency.

2. Expanded Applications: The potential applications of VIPs are expanding beyond traditional sectors. Emerging uses in automotive, aerospace, and consumer electronics are being explored, where superior thermal management is critical.

3. Cost Reduction Strategies: Ongoing research and development efforts are focused on reducing the production costs of VIPs. Economies of scale, improved manufacturing techniques, and the development of hybrid insulation systems combining VIPs with other materials are likely to make VIPs more affordable.

4. Regulatory Support: Continued regulatory support for energy-efficient building practices and sustainable construction will play a pivotal role in driving the adoption of VIPs. Incentives and subsidies for green buildings can further bolster the market.

Key Players

- Panasonic Corporation

- DowDuPont Inc.

- Evonik Industries AG

- LG Hausys Ltd.

- OCI Company Ltd.

- Kingspan Insulation, LLC

- ThermoCor

- Vacutherm Ltd.

- Va-Q-Tec AG

- Porextherm Dämmstoffe GmbH

Segments

By Type

- Flat Panel

- Special-shaped panel.

By Raw Material

- Silica

- Fumed Silica

By Core Material

- Silica-based Core

- Polyurethane-based Core

By End-User

- Construction

- Refrigeration and Cold Chain

By Region

- North America

- The U.S.

- Canada

- Mexico

- Europe

- Germany

- France

- The U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of Middle East and Africa

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: sales@credenceresearch.com