Support structures play a crucial role in 3D printing by allowing intricate and complex designs to be created with precision. A noteworthy development in this field is the emergence of Cura Tree Supports. These advanced support structures have become highly regarded within the 3D printing community due to their effectiveness in minimizing material wastage.

In this article, we will take a closer look at Cura Tree Supports, examining their definition, functionality, and their significant impact on the world of 3D printing enthusiasts.

What is the purpose of support structures?

3D printing is an innovative way of making things. It can produce complicated shapes. But sometimes, it needs some help to make these tricky shapes. Imagine it like constructing a sandcastle and having to add some more sand to keep your structures from falling.

You see, 3D printers challenge to create parts that protrude greatly or need to be joined in the air, like bridges between towering structures. This is because the material they use can’t defy gravity on its own. So, here’s where support structures step in. These supports are like scaffolding around a building being constructed. They’re made automatically by special software, such as Ultimaker Cura, and they help 3D printers make those overhangs and bridges.

Overhangs are parts of a 3D object that stick out at angles more than 45 degrees. Bridges, on the other hand, are flat structures that join two vertical parts. Supports are crucial for printing these in order to maintain the material in position as it is being added.

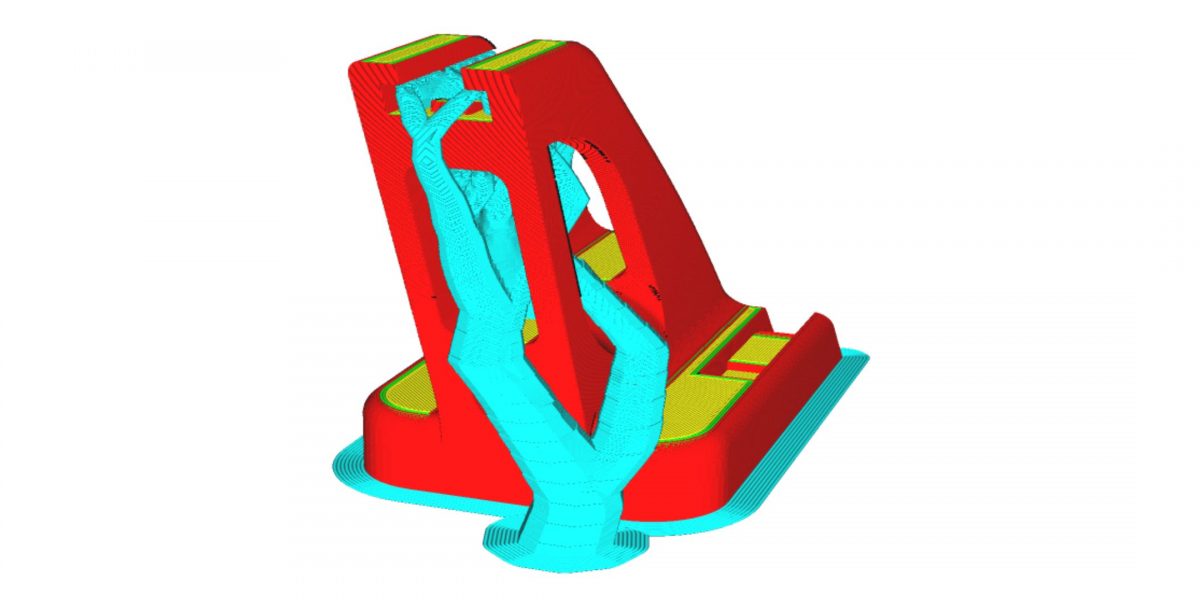

Support structures can be of two types: One is the regular kind, which looks like straight-up columns supporting the tricky parts. The other is tree supports. These supports are more like branches of a tree, wrapping around the object to provide support. They start wider at the bottom and get thinner as they go up, touching the printed part as little as possible. And when you’re done, they’re easy to remove, leaving you with your finished 3D creation.

What exactly are tree supports?

Tree supports are a special kind of support material designed to be efficient and strong. Think of them like trees – they have a thick base, like a tree trunk, and thin parts branching out in different directions.

These tree supports were first introduced in Cura version 3.2.0 back in February 2018. At first, you could only find them in the experimental section, but they became an official part of Cura in 2020 with version 4.7.0.

When you’re 3D printing, the trunk of the tree support gives your object strength, while the little branches hold up the tricky parts without sticking too hard to your model. This makes it easier to remove the support material without hurting your 3D print.

Because most of the tree support is hollow inside, it saves you time and materials compared to regular support structures. That means lower costs, which is great if you’re trying to make money with your 3D printer.

This Cura tree support works best for 3D printing small stuff like figurines, decorations, statues, and anything with a lot of overhanging parts. They help those overhangs and won’t leave many marks on your finished piece.

How Cura Tree Supports Work?

A process is taken in 3D printing with FDM to produce items. This is how it goes:

- Material Deposition: A print head is used to push out melted thermoplastic filament onto a base called the build platform.

- Layer by Layer: The material is laid down in thin layers, one on top of the other. Each layer solidifies as it’s deposited.

- Object Building: This process repeats over and over, layer by layer, until the entire object is formed. It’s like building a tower with lots of tiny bricks.

- Supports: Sometimes, as the layers go up, they need some extra help to stay in place.

Now, let’s talk about “Cura tree supports.” These are a bit special:

- Different Angles: Unlike regular supports that go straight up, tree supports can be printed at various angles. They wrap around the model, adapting to its shape.

- Reinforcement: These tree supports are smart; they provide extra support right where it’s needed most, using their branch tips. This not only helps in printing but also makes it easier to remove them later.

In Cura slicer software, you can control these tree supports using specific settings:

- Support Placement: You can choose between “touching build plate” or “everywhere.” The first option places support only on the base, while the second can add support to the model itself if necessary.

- Support Overhang Angle: This setting decides when and where supports are needed. Most 3D printers can handle overhangs up to 45° without supports, but you can adjust this angle.

- Support Branch Angle: Tree supports have this unique setting. It controls how wide the branches can go around your model. Higher values mean more freedom for the branches but could make them less supportive.

- Support Branch Distance: This setting determines how close the support branches are to the model’s edges. Closer distances mean stronger support but may be harder to remove.

- Support Branch Diameter: You can choose how thick or thin the branches should be. Thinner branches use less material, but thicker ones provide better stability.

- Collision Resolution: This ensures that the supports don’t get in the way of your model. A lower value gives more precise support, but a higher value can speed up printing.

So, these settings help you control how your 3D printer uses tree supports to make your objects solid and stable. It’s like giving your printer special instructions to build things just the way you want!

Benefits of Cura Tree Supports

- Improved Surface Finish

- Tree supports offer a significant advantage in achieving cleaner surface finishes.

- Traditional supports often necessitate adding features on outward-facing surfaces, like overhangs not directly above the print bed. The tree supports Excel in such cases.

- Selective Support Placement

- Unlike traditional supports, the “trunk” of tree support doesn’t touch the model.

- Branches extend only where needed, allowing the tree to overhang where the print cannot. This feature minimizes artifacts caused by upright supports, especially for organic shapes like humans and animals.

- Material and Time Savings

- Tree supports are designed to use less material compared to standard supports.

- The tree can be printed with low infill density or hollow.

- For a strong base, the trunk can have a denser infill at the bottom, reducing both material usage and printing time.

- Effortless Support Removal

- Tree supports have fewer contact points with the model.

- They lack solid “roofs” under the model, making support removal straightforward.

- There are no concerns about support structures fusing with the model, a common issue with traditional supports.

- Different infill densities make it easy to break away the tree and branches in chunks.

The tree supports enhance 3D printing in several ways. They ensure smoother surface finishes by strategically placing supports, saving materials and time through efficient design, and simplifying support removal due to their minimal contact points. Whether you’re crafting intricate designs or organic shapes, tree supports prove to be a valuable tool in achieving better 3D printed results.

Disadvantages of Cura Tree Supports

- Increased Slicing Time

One downside of using tree supports is that they demand more computer processing power compared to conventional linear supports. This is because tree supports have a more intricate design than linear ones, causing them to take longer to create in slicing software. Consequently, this extended processing time can partially offset the advantages of quicker support printing times, although this rarely nullifies them entirely.

- Not Ideal for Soluble PVA Supports

Tree supports can pose a particular challenge when you’re working with soluble support materials like PVA. This is due to their intricate shapes and geometries. PVA, in comparison to materials like PLA or ABS, is tougher to print, and as a result, some 3D printers may struggle to reproduce the finer details found in the upper sections of tree supports. Therefore, Cura suggests using its tree support feature primarily with non-soluble support materials.

Best Substitute to Cura 3D Printing: SelfCAD

SelfCAD is the and slicing tool that integrates design, technical, and 3D printineasiest 3D modeling software operations in a single place. Its cloud-based 3D slicing tool is what lets it stand out; all you need is an internet connection for use on your 3D models.

SelfCAD makes editing 3D models easy, even for beginners. Its built-in slicing software allows you to finely control print preparation and quickly slice your models. You can also estimate print times and material usage and catch common errors like layer height and infill density with a full-layer preview. It’s compatible with most FDM printers on the market.

Merits:

- No need for downloads; you can edit your STL files online.

- Compatible with most FDM 3D printers.

- Requires minimal technical expertise; you can easily tailor the slicer to your needs.

- You can check material usage and print time for your designs.

- Adding support and other critical settings is straightforward.

Pricing: SelfCAD offers a free version with a limited toolset. Paid options include a $599 perpetual license, a $14.99 monthly plan, or a $139.99 yearly subscription.

Perfect Prints with Cura Tree supports:

Cura Tree Supports has emerged as a game-changer in 3D printing. They offer efficiency, material savings, and improved print quality while simplifying post-processing. Embracing this innovative support structure not only streamlines the printing process but also opens up new possibilities for creating intricate and complex designs with ease.