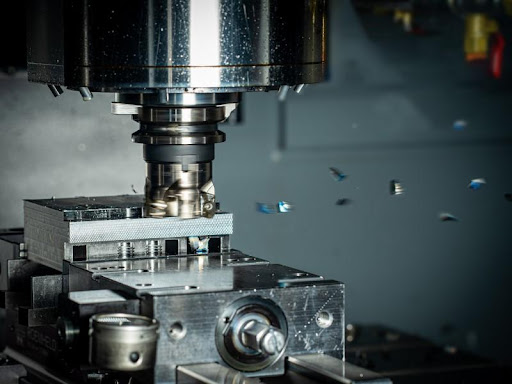

The CNC machined prototypes are an excellent way to create a physical product from a digital design; it is a manufacturing process using computer-controlled machines to quickly and efficiently develop prototypes. It allows for modifications and iterations to be made before mass production begins. For manufacturers, this process can save time and money in the long run and it helps to produce high-quality final product.

Speed

CNC machining is widely used for mass production. It is a highly automated process that can produce large quantities of parts quickly and accurately, allowing manufacturers to test their products before mass production. The method uses high-speed machining tools to remove material from a workpiece. It helps make it ideal for production runs of complex parts.

The manufacturing process can be used to produce parts from a variety of materials, including metals, plastics, and composites.

Tooling – CNC Machines will run without tooling and dies

CNC machines are computer controlled and can run without tooling or dies. Companies can a wide variety of parts without investing in costly tooling, saving money.The subtractive manufacturing process helps to remove raw material with various precision cutting tools to make a very high degree of accuracy part or product. The use of advanced software also reduces the need for manual labor, which can help to reduce costs.

Accuracy and Precision

Accuracy and precision are both major factors to consider when taking measurements. The process can be used to create parts of any size, from small components to large assemblies. The machines can be controlled in this manner include CNC lathes, mills, routers, and grinders. CNC machines are often used when high levels of both accuracy and precision are required.

Control and Modifications

There are multiple ways to modify and control a CNC machine. The most common method is through the use of G-code, which is a set of instructions that tell the machine what movements to make to create a specific shape or object.

This process can be used to create or modify parts for a variety of different products. CNC Machining is typically used for metals but can also be used for plastics and other materials. The process typically involves using a cutting tool but can also include additional tools such as drilling and milling.

Material for CNC Machine

The versatile manufacturing process that can produce complex parts from a wide range of materials. It is often used for high-volume production of components with tight tolerances. It is using to manufacture parts from a variety of materials. The most common materials used in CNC machining are metals, plastics, and composites, but other materials such as glass and wood can also be machined.

The type of material that is used in CNC machining affects the properties of the finished part, so it is crucial to select the suitable material for the application. For example, parts that need to be strong and durable may be made from metals such as steel or aluminum, while parts that need to be lightweight and resistant to corrosion may be made from plastics or composites.

High-Quality Surface Finish

The advantages of CNC machines are that they are highly precise and offer a high-quality surface finish. This is because they use computer-controlled machining processes that allow for exact control over the machining process. This results in a surface finish that is very smooth and consistent. Additionally, CNC machines can also be used to produce very intricate designs and complex shapes which is very difficult or impossible to produce using other methods.

CNC Machine Short Run

CNC machine services offer short-run production services for companies that require a lower volume of parts than what is typically produced in mass production. This type of service is ideal for companies that are prototyping a product or need a small batch of parts for testing purposes. CNC machining is a type of computer-aided manufacturing (CAM) where software controls machine tools’ movement.

CNC manufactured parts are parts that are made using a CNC machine. CNC machined parts are commonly used in the aerospace, medical, and automotive industries. Where time is of the essence, CNC has become increasingly popular for rapid prototyping in recent years due to its accuracy and speed.

FAQ:

What is rapid prototyping in CNC?

Rapid prototyping in CNC is a process of creating prototypes using computer-controlled machine tools. The advanced manufacturing process is faster and more accurate than traditional methods, allowing for the creation of complex shapes. This process can be used to create both functional and non-functional prototypes and can be an invaluable tool in the product development cycle.

Why Choose CNC Machining for Rapid Prototyping?

There are many reasons to choose CNC rapid prototyping for your manufacturing needs. It is an excellent option for many different applications. It can be used for creating prototypes of products or even for creating production-ready parts in small batches without the need for expensive tooling.

How do I save the costs of CNC prototyping?

There are a few ways to save on the costs of CNC prototyping. One way is to use lower-cost materials such as aluminum or plastic instead of more expensive metals. Another way is to use less costly manufacturing methods, such as 3D printing or injection molding. Use an existing part or mold. If you have an existing part or mold that can be used for your prototype, this can save on machining costs.

What type of prototyping does a CNC machine use?

A CNC machine uses a type of prototyping known as computer numerical controlled (CNC) machining. This process involves using a computer to control the movements of a cutting tool, which is used to create the prototype.