Medical molding plays a pivotal role in the production of precise components for medical devices, ensuring quality and reliability in the healthcare industry. When embarking on a new project that involves medical molding, calculating the trial cost of the mold is a crucial step in the manufacturing process. In this article, we will explore the factors influencing the trial cost of a medical molding mold and provide insights into how to make accurate calculations.

Understanding the Components of Trial Mold Costs:

- Material Costs:

The choice of materials for the mold significantly impacts the trial cost. High-quality, durable materials are essential to meet the stringent requirements of the medical industry. Consider the volume and type of material needed for the trial mold, as it sets the foundation for the overall cost calculation.

- Design and Engineering:

The complexity of the mold design and the engineering involved play a pivotal role in determining trial costs. Intricate designs or custom specifications may require additional engineering efforts, contributing to higher costs. Collaboration between designers and engineers is essential to optimize the design for efficiency and cost-effectiveness.

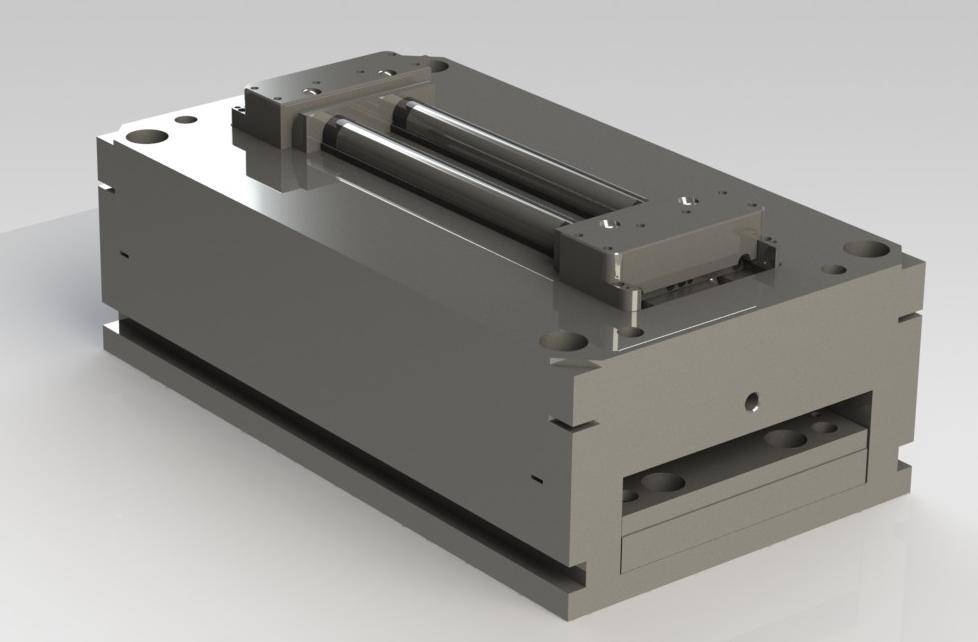

- Machining and Tooling:

Machining and tooling costs are critical components of the trial mold cost. The precision required for medical molding molds demands advanced machining techniques. Consider the intricacy of the mold design, the number of cavities, and the materials used in the machining process when calculating these costs.

- Labor and Skill Level:

Skilled labor is essential for the successful creation of a medical molding mold. The expertise required for mold fabrication, assembly, and testing influences labor costs. Consider the skill level of the personnel involved and factor it into the cost calculation to ensure accurate estimations.

- Prototyping and Testing:

Prototyping and testing are integral parts of the trial mold process. Building prototypes allows for the identification of potential issues and the refinement of the mold design. Testing ensures that the mold meets the required specifications. Both of these phases contribute to the overall trial cost and should be included in the calculation.

Steps to Calculate Trial Mold Costs:

- Gather Detailed Specifications:

Collect detailed specifications for the trial mold, including material requirements, design intricacies, and any specific engineering considerations. The more comprehensive the information, the more accurate the cost estimate will be.

- Consult with Engineers and Designers:

Engage with your engineering and design teams to discuss the intricacies of the mold. Consider their insights on potential challenges, required adjustments, and any recommendations for cost-saving measures. Collaboration at this stage can lead to a more efficient and cost-effective mold design.

- Obtain Material Quotes:

Contact material suppliers to obtain quotes for the materials needed for the trial mold. Ensure that the selected materials meet regulatory standards and are suitable for medical molding applications. Material costs can significantly impact the overall trial cost, so obtaining competitive quotes is crucial.

- Assess Machining and Tooling Costs:

Work with machine shops or tooling manufacturers to estimate the costs associated with machining and tooling. Consider the complexity of the mold design, the number of cavities, and the materials used. Obtain multiple quotes to compare costs and select a provider that offers a balance between quality and affordability.

- Estimate Labor Costs:

Calculate labor costs based on the estimated time required for mold fabrication, assembly, and testing. Consider the skill level of the personnel involved and factor in any additional costs associated with specialized expertise. This step provides a realistic projection of the human resources needed and associated expenses.

- Factor in Prototyping and Testing:

Include costs associated with prototyping and testing in the overall calculation. Prototyping may involve multiple iterations to refine the mold design, and testing is essential to ensure that the mold meets performance and quality standards. Allocate resources and budget for these crucial phases of the trial process.

- Contingency Planning:

Building in a contingency factor is prudent to account for unforeseen challenges or changes during the trial mold process. A contingency budget provides a financial buffer to address unexpected issues without derailing the entire project.

- Review and Finalize:

Review all cost estimates, ensuring that each component is accounted for and that the calculations align with the project’s objectives. Seek input from relevant stakeholders, including engineers, designers, and financial decision-makers, to finalize the trial mold cost estimate.

Conclusion:

Calculating the trial cost of a medical molding mold is a comprehensive process that requires careful consideration of various factors, from material selection to labor costs and prototyping. Accurate cost estimation is essential for budgeting purposes and ensuring the success of the overall molding project.

By following these steps and collaborating effectively with engineering and design teams, manufacturers can derive a realistic and well-informed trial mold cost estimate. This approach not only facilitates efficient budgeting but also sets the foundation for a successful medical molding process, delivering high-quality components for the healthcare industry.

In the dynamic and precision-driven world of medical molding, a thorough and accurate trial mold cost calculation is a key step towards achieving optimal results in product development.